Port Turnaround Optimization

Why It Matters More Than Ever

The efficiency of port operations isn’t just a technical benchmark, it’s the backbone of global supply chains and a critical factor in attracting and retaining business. As ports increasingly become central decision points in supply chains, here’s why port turnaround optimization deserves your attention.

1. Visibility in port turnaround time drives performance

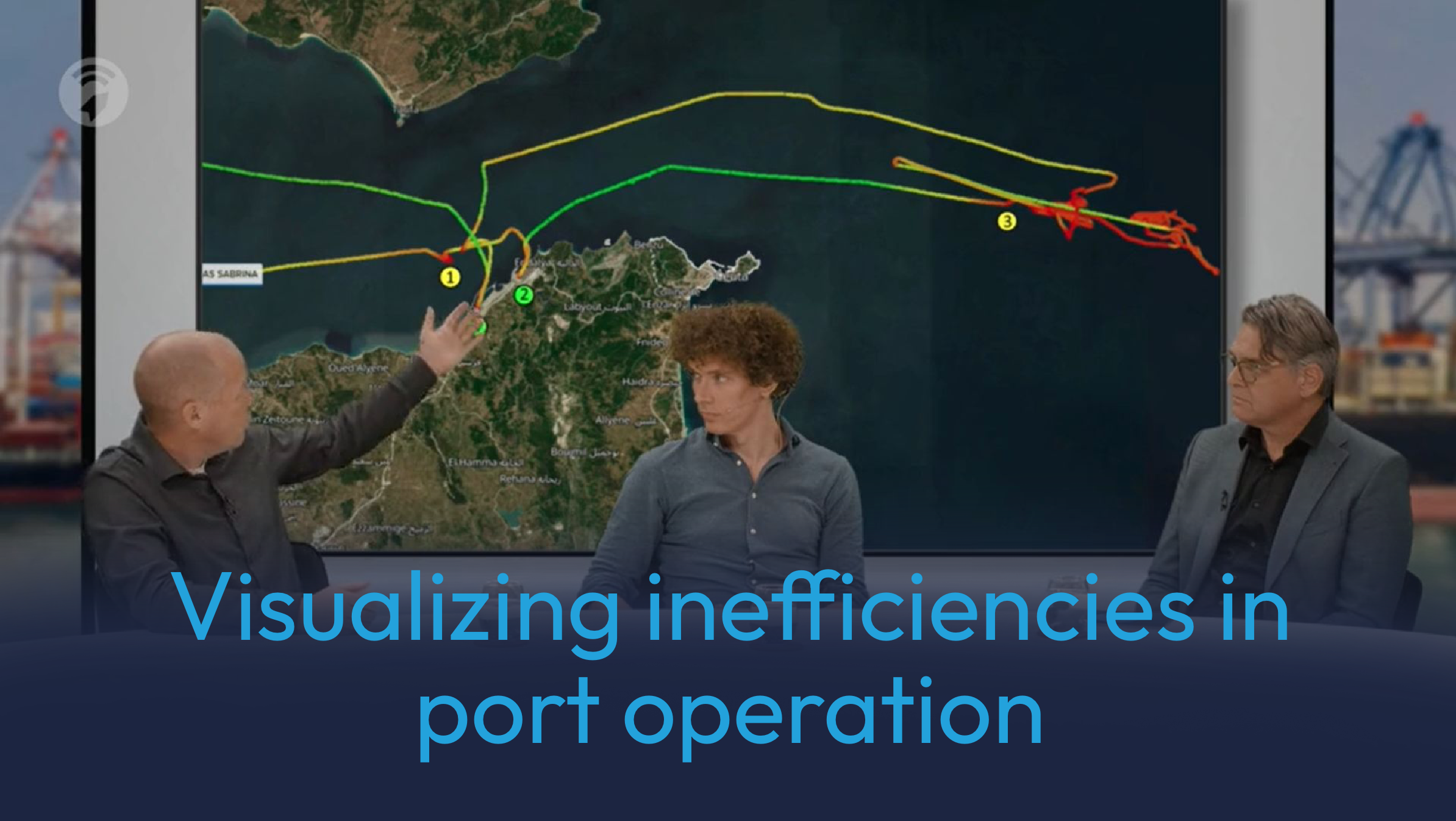

Ports function as orchestrators of cargo flow rather than outright owners. By harnessing objective data and employing time-stamped process monitoring, ports can unlock actionable insights into their performance. For instance, analyzing terminal operations and nautical services can uncover bottlenecks, leading to productive, data-driven dialogues with stakeholders. These insights enable targeted interventions to keep cargo moving efficiently.

Visibility is also key to building trust and collaboration across the supply chain. When stakeholders, including shipping lines, terminal operators, and logistics providers, have access to the same data, it becomes easier to align expectations and synchronize efforts. This level of coordination minimizes disruptions and ensures smoother operations from arrival to departure.

2. The cost of waste in port turnaround

Unpredictability often fuels inefficiency. Here are some common scenarios at container terminals:

Surprise delays: Vessels arriving earlier or later than scheduled without proper notification.

Resource mismatches: Misaligned schedules causing cranes or yard teams to be unprepared.

Stacking errors: Containers placed sub-optimally, leading to increased handling times.

Each small inefficiency compounds, creating ripple effects, especially for large vessels managing thousands of container moves per call. The cumulative cost of these inefficiencies isn’t just operational; it’s financial and reputational. A port’s ability to minimize such waste directly impacts its throughput and competitiveness.

Consider this: a single delay in unloading or loading can disrupt schedules not only at the port but across entire supply chains. This can lead to increased fuel costs, missed connections, and dissatisfied customers – problems that could have been avoided with optimized operations.

3. What’s at stake?

Port turnaround time isn’t merely a metric, it underpins throughput, customer satisfaction, and profitability. Dynamic response capabilities and real-time operational optimization ensure ports stay competitive and attractive to global trade networks. Ports that adapt quickly to deviations and optimize their workflows are the ones setting the industry standard.

Beyond competitiveness, efficient turnaround times contribute to sustainability goals. Reducing idle times and unnecessary resource consumption lowers emissions and aligns port operations with environmental initiatives. As industries worldwide face increasing pressure to adopt greener practices, ports have an opportunity to lead by example.

4. The path forward

The solution lies in leveraging technology to enhance visibility, identify inefficiencies, and prioritize improvements. Real-time insights, shared across port authorities, terminals, and stakeholders, facilitate smoother operations and better outcomes. Embracing data-driven strategies isn’t just an option; it’s a necessity for future-ready ports.

Investing in predictive analytics and digital twin technology can further elevate port performance. Predictive tools help forecast potential delays, allowing ports to allocate resources more effectively. Digital twins enable scenario planning and rapid response to unexpected events, ensuring continuous improvement.