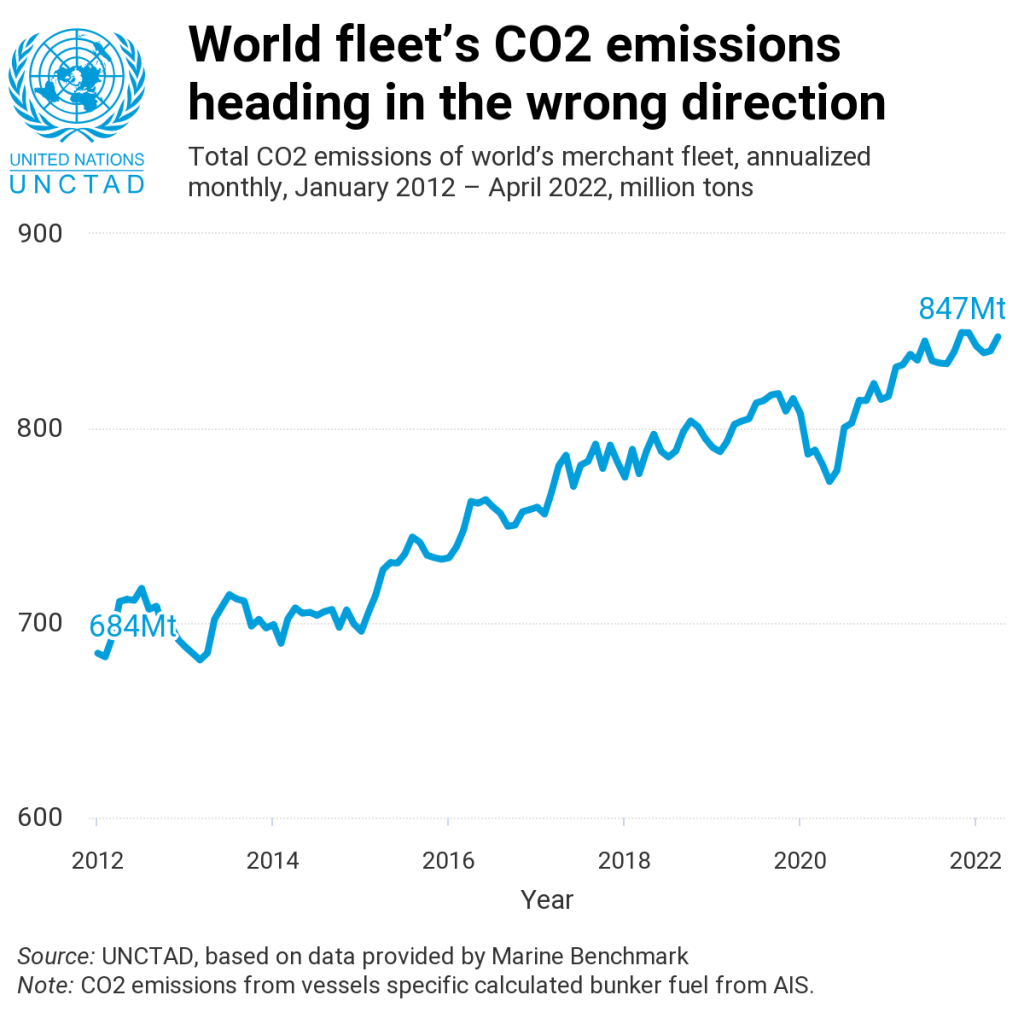

In UNCTAD’s 2022 Review of Maritime Transport, the state of GHG emissions in the maritime industry is in urgent need for action:

The UNCTAD is calling for “more investment in energy-efficient shipping technologies and an accelerated shift to alternative, low-carbon fuels to cut the carbon footprint of maritime transport”.

For port actors, decarbonizing and optimizing the port call process go hand-in-hand with each other. When energy-efficient technologies are properly employed and port activities are optimized, carbon footprint can be reduced and decarbonization will be more easily achieved.

Port call optimization

Port call optimization solutions can use advanced analytics and data from various sources such as weather, traffic, and vessel schedules to optimize the planning and scheduling for port calls. This can help reduce the amount of time ships spend in port, which in turn reduces emissions from the ships and the number of port-related truck and train trips. With strategic use of digital solutions, port operators can plan for the most efficient use of resources and minimize delays. By building a digital twin that reflects port events in real-time, port actors will also have the context to make better decisions for carbon footprint, such as reducing the number of ship-to-shore crane moves. Investing in the right technology will ensure efficiency and minimize environmental impact for every step of the port call process.

Remote monitoring and control

Remote monitoring and control systems can also be set up to monitor and control ship systems from a remote location, reducing the need for on-board crew to attend to routine tasks during port calls. Along with remote systems, port community systems can also be developed as support. These are digital platforms that connect all stakeholders in a port ecosystem, such as shipping lines, terminal operators, customs, and logistics service providers. They can be used to optimize the flow of information and cargo, reducing emissions from the movement of goods and people.

Predictive capability

Predictive capability and visibility is also important in achieving optimization goals and reducing carbon footprint. Predictive analytics can be used to predict the arrival and departure times of ships, the volume of cargo, and the resources that will be needed. By analyzing historical data, port operators can predict future trends, and make decisions that will lead to increased efficiency and reduced environmental impact. With better prediction and visibility, a lot of waste can be avoided which will bring long-term benefits for both maritime businesses and the environment.

Digital infrastructure

Investing in digital infrastructure is also necessary to ensure smooth implementation of the aforementioned solutions. IoT and sensor-based systems can be used to track and monitor the movement of goods and equipment within ports, as well as provide accurate and real-time data. The data collected from IoT devices will need to be stored, analyzed and processed in real-time. A cloud-based infrastructure is necessary to allow for scalability and flexibility, enabling the data to be accessed from anywhere, at any time. This is particularly important considering the complexity of port networks involving multiple stakeholders, from shipping lines, terminal operators, customs, to logistics service providers, all of whom need access to real-time data. With quality data and a powerful cloud computing platform, innovative solutions can be more easily enacted.

Teqplay

Teqplay believes that implementing energy-efficient technologies is key to achieving decarbonization for the maritime industry. As the maritime world evolves, demands increase, and climate change becomes more severe, it is up to businesses to make the most out of technological developments and take action to promote a sustainable future.

Léon Gommans | CEO/Co Founder of Teqplay

A serial entrepreneur who’s passionate about #innovation, #technology, #collaboration, and of course, #maritime. The mission is: to connect the dots & to get it to work, together with the industry!

- +31 (0)6 55306660

- leon@teqplay.com

- Léon Gommans