Port Call Optimization

A reliable port always looks for the most optimal solutions for their port calls. Port call optimization is an important step toward a future of resilience and sustainability for the maritime industry. Moreover, in order to effectively optimize port calls, maritime stakeholders also need to look beyond the port and have a comprehensive view of cargo movement.

What is port call optimization?

When managing a supply chain, increasing efficiency is always at the core of all strategies. In fact, it can be said that the goal of supply chain management is optimization. As an important part of the maritime supply chain, the port call also requires similar attention and effort.

In short, port call optimization is the effort of various stakeholders and actors involved, made with the purpose of maximizing the utilization of resources while minimizing waste. The advantages that a successful optimization strategy bring are manifold, from environmental benefits to cost and fuel saving. It is no wonder why the parties involved would always try to devise the ideal strategy for port call optimization.

However, in reality, there is no one ideal path toward the optimization of the port call. Each party has a different priority and thus a different approach toward what they consider to be optimized. Furthermore, depending on whether the focus is on the operation of the port, the terminal or the ship, the solutions will also look different. On top of that, every port and/or ship will have their own approach and processes that need to be considered.

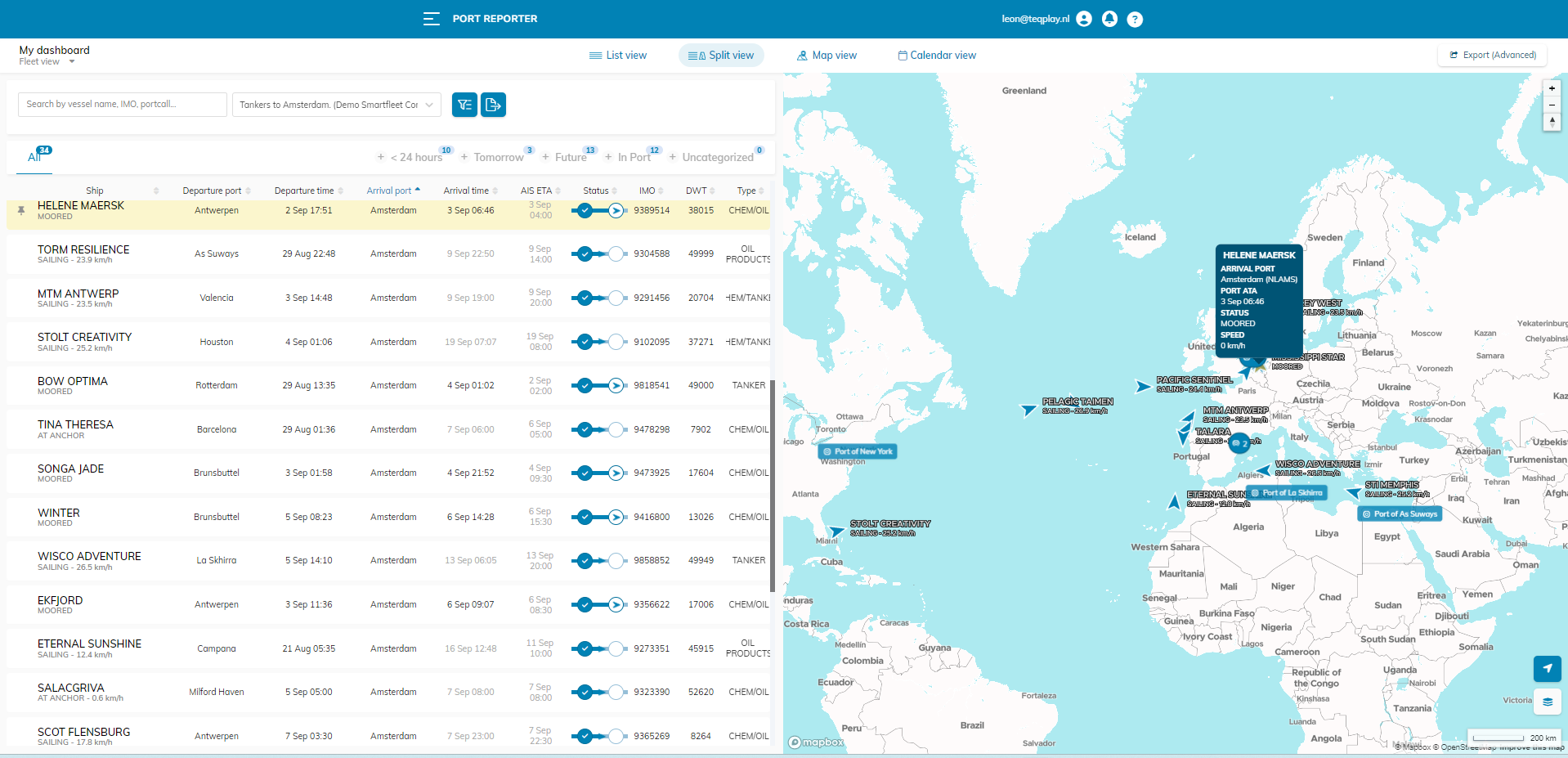

Source: Mikael Lind

The port call process is complex, including many subprocesses and involving many actors at the same time. For the sake of efficiency, companies need to understand time in port. Understanding time in port enables optimization of time waste in port through operational efficiencies and measurement of performance and/or mitigation of lost time through better contracting.

Furthermore, port call optimization is not just about the port call, but really about the movement of cargo on the vessel, from land port(s) to discharge port(s). As crucial as the port is in this process, we also need to have a comprehensive view of cargo movement as well. In this sense, port call is not all there is.

Why does port call optimization matter?

1. Increase predictability

Traditionally, ports operate on a first-come first-served basis. Nowadays, the demand for emission reduction and the need to increase efficiency require a better approach in planning. Predictability is the first key aspect that needs to be improved in order to realize just-in-time shipping.

Just-in-time (JIT) is a concept that has revolutionized the supply chain in the modern age. In the maritime industry, it has always been a particularly difficult initiative which promises great change and improvement when successful. Predictability is the foundation on which JIT is built, the first step in port call optimization. The ability to accurately anticipate vessels’ arrivals will increase the synchronization of the interaction between port and ship. A synchronized operation is undoubtedly beneficial for all parties involved, as it would reduce much of the costly waiting time that plagues the industry.

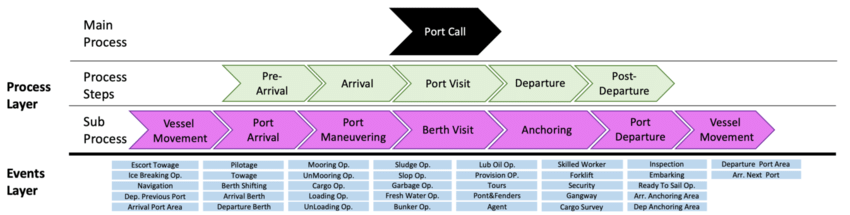

2. Reducing CO2 emissions; Eco speed sailing

Environmental impact is one of the biggest drivers of port call optimization. Climate change has been a global concern for quite a while, with more and more regulations coming into play for various sectors. The maritime industry is no exception to this, so businesses would need to adapt quickly in order to remain both sustainable and competitive.

In terms of port calls, delays greatly affect fuel consumption and thus emissions. Every hour a ship remains idle in port, it loses an hour of steaming time and therefore must sail faster to maintain its schedule. While the speed difference is ultimately marginal, it typically has a significant impact on a vessel’s fuel consumption and greatly increases emissions. In order to avoid this, it is important to achieve JIT and employ eco speed sailing. The sailing speed would constantly adjust to fit the situation and minimize waiting time, helping both ship and port to avoid wasting necessary resources.

3. Shorter port stay

Ever since the summer of 2020, the shortage in port infrastructure has urged the industry to find solutions to optimize port operations (Lind et al., 2021). Disruptions and uncertainties can easily cause congestion, forcing vessels to remain much longer than anticipated. This heavily affects cargo flow, and a single incident would cause a chain reaction where one delay would lead to the next. Thus, it is incredibly important to shorten port stay and reduce the burden on port infrastructure and labor.

4. Exposure of risks

Businesses in the maritime industry constantly face risks from different sources. The goal of many organizations in the industry is to mitigate these risks and ensure smooth financial performance. However, the constant exposure to disruptions and unpredictable events which cause delays means that it is very difficult to maintain control.

In the process of port call, waiting is itself a risk. When a ship is idle, the use of assets and resources of the ship would be inefficient. With each inefficiency, another cost arises, exposing the operation to potential financial troubles. Worst of all is when the disruption of ship operations e.g. directly affects production such as steel plants. In cases like these, the financial impact would undoubtedly be enormous.

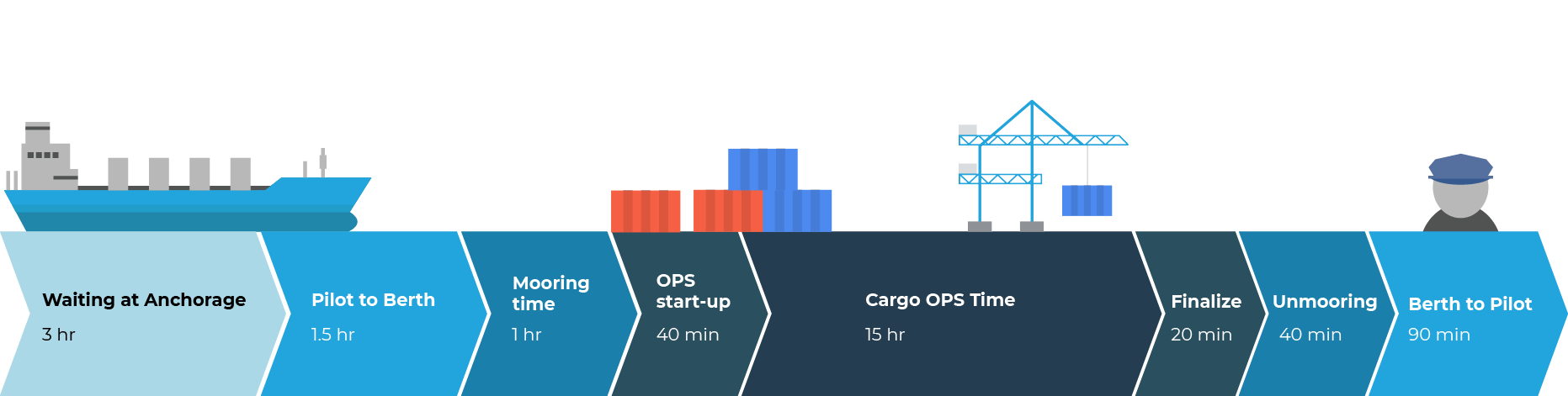

5. Digitalization and data-driven

Due to their complexity, port operations produce enormous amounts of data. Digitalization is necessary to ensure that these data would be recorded and utilized effectively. Having high quality information is a powerful advantage, a fact that has become especially true in this data-driven digital age.

Broadly speaking, digitalization is a much needed first step in changing the industry for the better. In practice, this initiative relies heavily on quality data and the ability to turn these data into useful insights. Digitizing data is necessary to improve synchronization and information access, all of which would impact the overall efficiency of operations and decision-making. Furthermore, when considering the human factor, digitalization is especially necessary in assisting agents and operators with maintaining their control and mitigating possible errors.

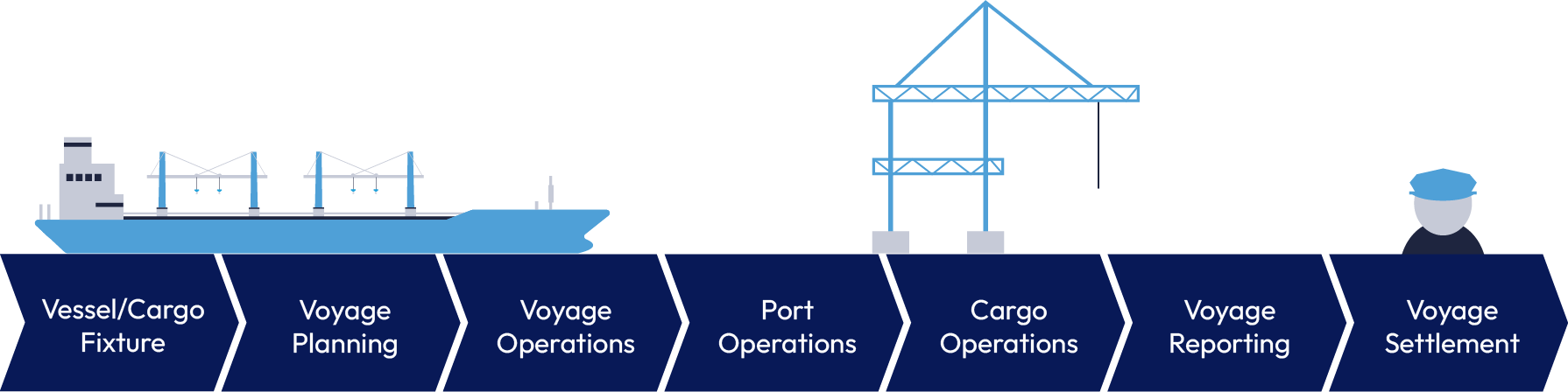

A deep dive into the port call process

1. The process

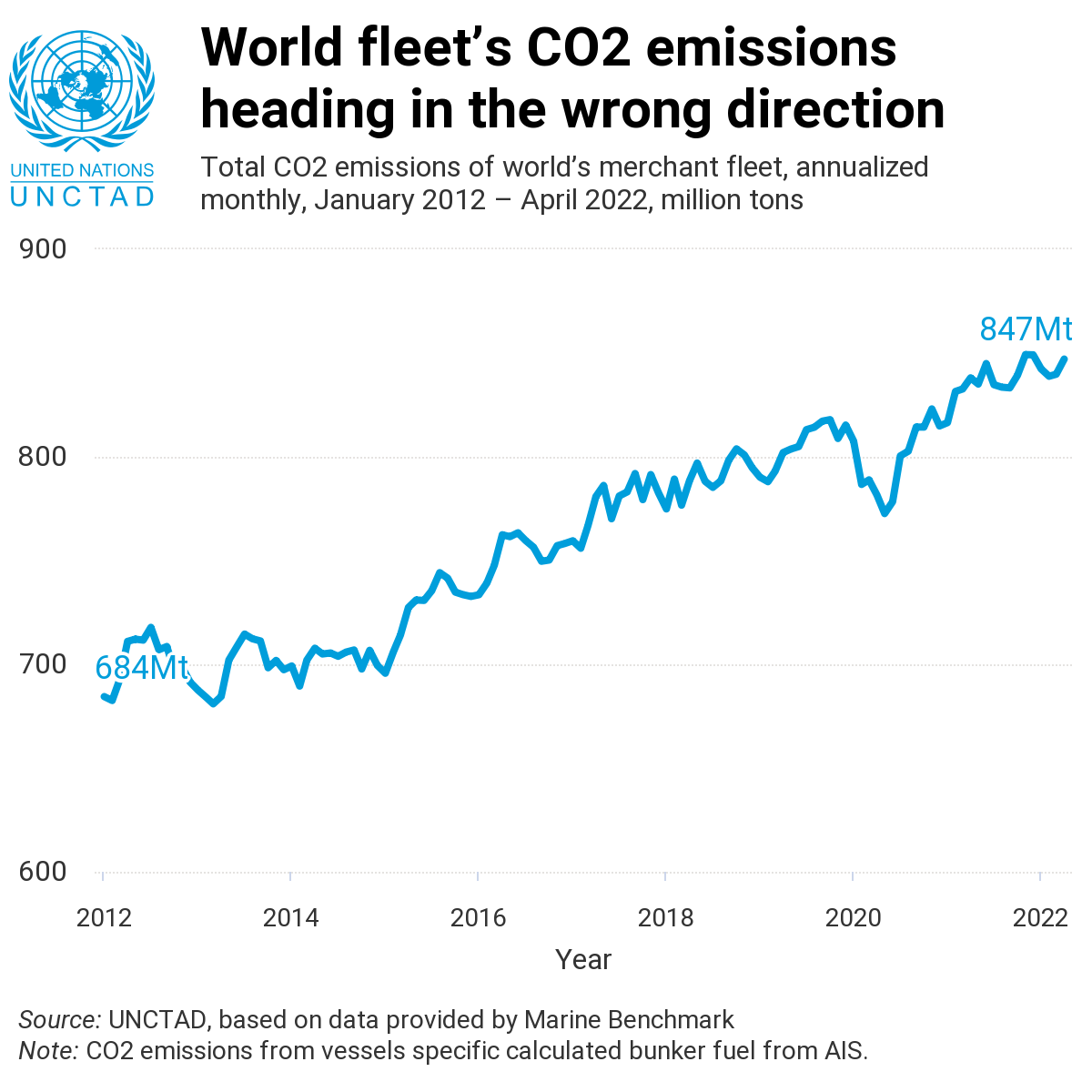

In theory, the port call process is straightforward. We have a vessel approaching. It has a port stay, doing cargo operations, and then it’s leaving the port. With such an explanation, it is difficult to fully grasp the complexity of a port call. In practice, port call operations require a high level of collaboration and alignment between many different actors.

At its core, a port call is the interaction between a vessel and the port. The process begins right at the nautical procedures, where pilots and boatmen need to ensure that the vessel is safely secured. Cargo inspections, including surveys, occur along these operations. An entire terminal exchange takes place among the various activities.

The port call process is not linear, and each actor is constantly executing a different task at the same time. At any given moment, up to 28 actors could be engaging in the process. The scheduling and planning of a port call can also look different. Liner services have fixed schedules and rotations, whereas in spot, the schedule is dependent on individual contracts between the charterer, shipowner and the terminal. Adding to the complexity of the process, vessels also need to be reported 24 hours in advance to be allowed in the port.

In a port call, each party has their own priorities which may overlap. A port centric approach will need different considerations from a ship centric perspective. Ports look for opportunities to expand the flexibility in planning, while shipping lines are concerned with utilizing ship resources efficiently. Both parties are constrained by each other’s schedules. Different ports are also not managed the same way, making standardizing difficult and requiring other parties to adapt.

Moreover, the optimization of operations goes beyond the port call; stakeholders also need to take into account the cargo movement process. Since the port is the center of maritime operations, it is easy to tunnel your focus into a singular port call when planning optimization strategies. While the port is key to maritime activities, if we only look at port calls, we will not have the context necessary to fully understand the scale of the cost and time wasted. The ‘what’ and ‘why’ behind port times and port cost go beyond the port call. It is also about the movement of cargo and cargo flows. When looking at optimization in a cargo perspective, at least two port calls are always involved.

2. The challenges

On top of possible complications due to all the variables involved, the port call process also faces many challenges when it comes to optimization. Looking at the industry, it is possible to identify what needs to be addressed in order to achieve optimization:

Limited digitalization

Digitalization is a necessary and inevitable part of the maritime industry’s progress. In broad terms, digitalization is the solution for much of the trouble concerning inefficiency in the port call process. Despite this, digitalization remains limited in the maritime sector.

The industry processes enormous physical volumes, but in reality, the number of port calls is low with a merchant fleet of 54.000 and 4.2 million port calls annually. In many cases, excel sheets and even a white board are still the main tools for planning and communications. The rapid changes in the industry demand operators to coordinate efficiently, and staying reliant on traditional methods would hinder optimization efforts.

Limited standardization

Limited standardization means that the use of external data in processes is risky and cumbersome. The use requires awareness of the different interpretations and requires translation and/or mapping. For instance: what does ETA mean, is it an ETA-port, ETA-pilot boarding place, ETA berth or any of the other options?

Low data availability

Limited digitalization and standardization means that the data necessary to facilitate optimization is often also unavailable, resulting in an inability to share information. Data availability is a significant bottleneck in the port call optimization process, highlighting the necessity to digitize procedures in the industry.

Reluctance to share data

Also relating to the limited progress in digitalization, vital information is not always easily accessible due to their lack of digital availability. Operators and agents most commonly coordinate their activities through phone calls, documents, and emails. In between these efforts, information is not updated in real-time nor is it available to every relevant stakeholders. The disconnect in information sharing makes it difficult to coordinate and leads to more inefficiency.

On top of the digital unavailability of information, there is also the challenge of reluctance in data sharing. For many in the maritime industry, the data they hold could be their business advantage. There are many complications that could arise in the process of data sharing among organizations, and solving this conflict could be the key to improving collaborative efforts.

Every port is different; every process is different

As a whole, ports are always focused on optimizing their resources and infrastructure in order to receive all types of shipping lines at the same time. From containers to wet and dry bulk as well as passenger ships, there is quite a variety of trades that pass through a port, each requiring different procedures.

Even in one country, each port differs from the other in how they carry out various processes. When accounting for the concerns of shipping lines and the differences in international legislations, this creates a complicated formula which challenges port call optimization efforts.

Everything is connected: delay causes more delay

As a continuous process, every step of one port call could affect the next one, creating a cascading effect and disrupting the wider supply chain in some cases. In this sense, the process can be quite delicate, requiring strong collaboration and precision in execution. Human error is also a great concern, thus technological initiatives are becoming increasingly necessary to aid in both coordination and risk reduction.

Teqplay’s Vision on how to improve port calls

The maritime industry is pushed to contribute to the net-zero by 2050. Many initiatives are taken to achieve this challenging goal. Legislation is brought into play by bodies like the IMO and local governments or authorities with examples like the CII. We expect the industry to be forced to bring data and technology into play in order to achieve the targets. We expect the maritime industry in 2030 to be held accountable for the net-zero commitments. And these will have to be backed by credible action.

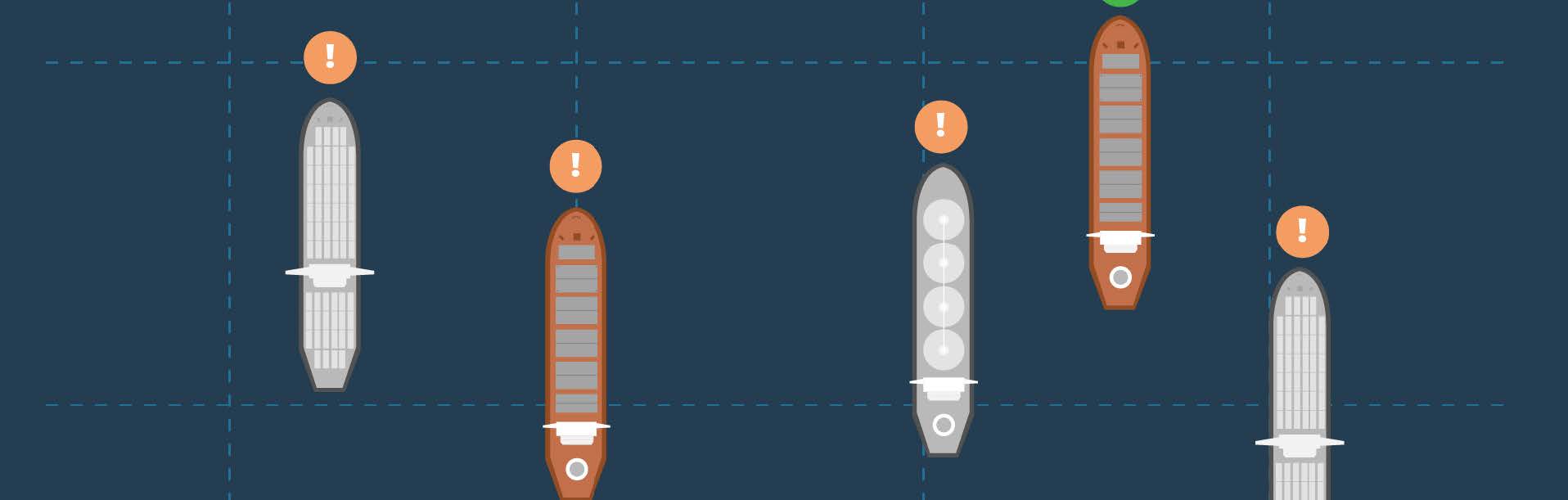

As has been established, in order for the industry to move forward, we need to solve the challenge of leveraging technology and improving collaboration between various actors. Operational excellence is the goal of most maritime organizations, but between managing various expensive assets and coordinating many groups of people, there are always complications.

The maritime world is too big and interconnected for an individual or a single group to comprehend and interpret, meaning that data-driven decisions are incredibly important. In order to obtain high quality data, it is essential to collect information from various connected systems and create a comprehensive picture of operations.

Ultimately, the aim is to find insights that are actionable and applicable to daily operations. This will directly aid important decision making, ensuring that all the choices made have a strong basis in real-time updates of information and events.

In short, context is king when it comes to data-driven decisions. It is crucial to accurately map out the context of all information obtained. Decisions cannot be made in a vacuum, and it is especially important to have a good overview of all events before deciding on a course of action. One solution might work in the short-term, but without truly understanding the background information and root cause of disruptions, there is a risk of unforeseen consequences.

Operating based on deep insights backed up by contextualized data will enable positive change in the industry. Port call optimization cannot be achieved without change and innovation, requiring stakeholders to be aligned in strategic thinking. To combat disruption and stay on top of future development, the maritime industry needs a fresh approach and a strong commitment to digitalization.

How port call optimization benefit you

Port authorities

By reducing idle time and optimizing the quays and cranes, ports can benefit significantly. Ports will be able to handle more vessels, reduce congestion issues and improve cargo flow. Port call optimization enables port authorities to become more flexible in their planning and scheduling.

Terminals

Reliable and real-time information on the arrival of vessels can help terminals improve their berth planning. If the work is more efficiently conducted, it will also result in happier customers for the terminal.

With the help of JIT arrivals, maritime businesses can reduce their emissions and bunker consumption. Since port calls will be conducted faster, vessels and container fleets will operate more efficiently.

Shipping lines

With better visibility and higher predictability, port calls can handle more operations and control what goes on in the port more easily. As emissions are reduced and the efficiency is boosted, agencies will be more competitive.

Agents

With port call optimization, agents are more free to act. Their efforts can now be focused on further improving their services and allocating their time appropriately in more relevant activities.

Cargo owners

Thanks to optimized port processes, cargo owners reduce the risk on delays and disruptions that impact the quality and cost of shipping. With a reliable shared point of truth, cargo owners can also keep track of events in and around the vessels in ports and stay aware of any important events or issues.

Download Teqplay’s Port Call Optimization white paper & more here

Léon Gommans | CEO/Co Founder of Teqplay

A serial entrepreneur who’s passionate about #innovation, #technology, #collaboration, and of course, #maritime. The mission is: to connect the dots & to get it to work, together with the industry!

- +31 (0)6 55306660

- leon@teqplay.com

- Léon Gommans