All maritime stakeholders want their operations to be optimized and efficient. The question is, how?

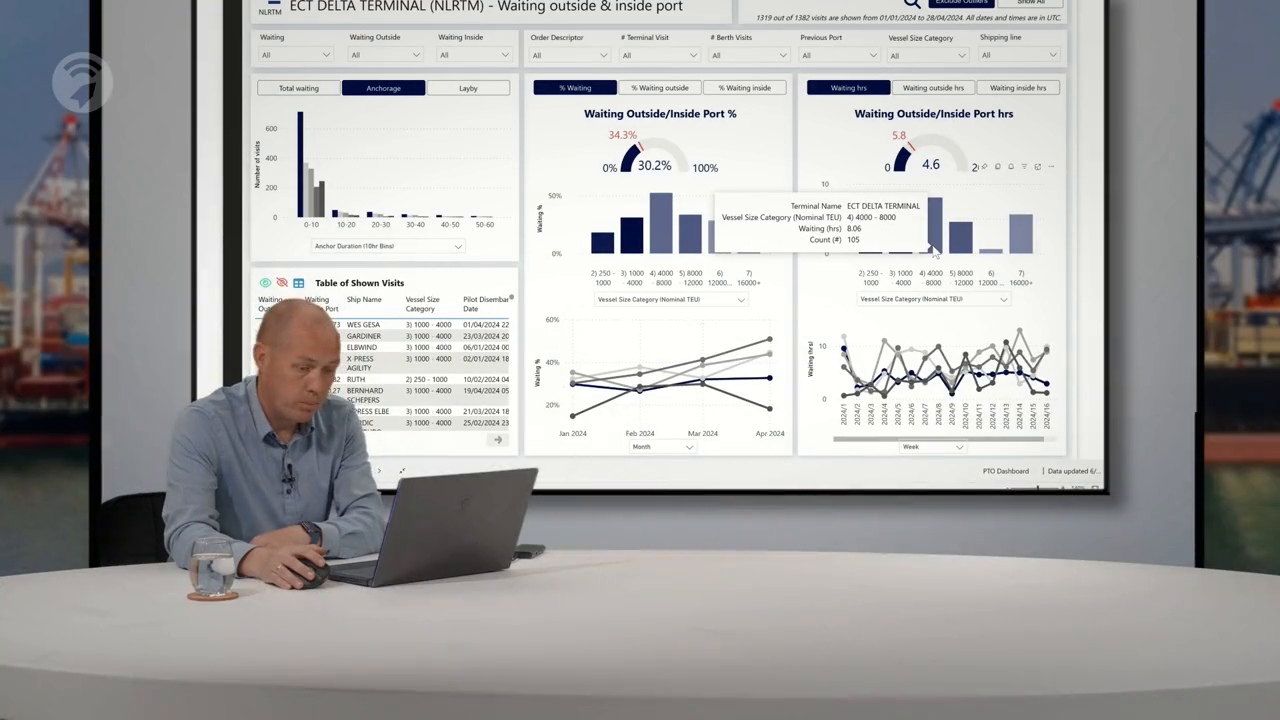

The port call process is complex, including many subprocesses and involving many actors at the same time. For the sake of efficiency, companies need to understand time in port. Understanding time in port enables optimization of time waste in port through operational efficiencies and measurement of performance and/or mitigation of lost time through better contracting.

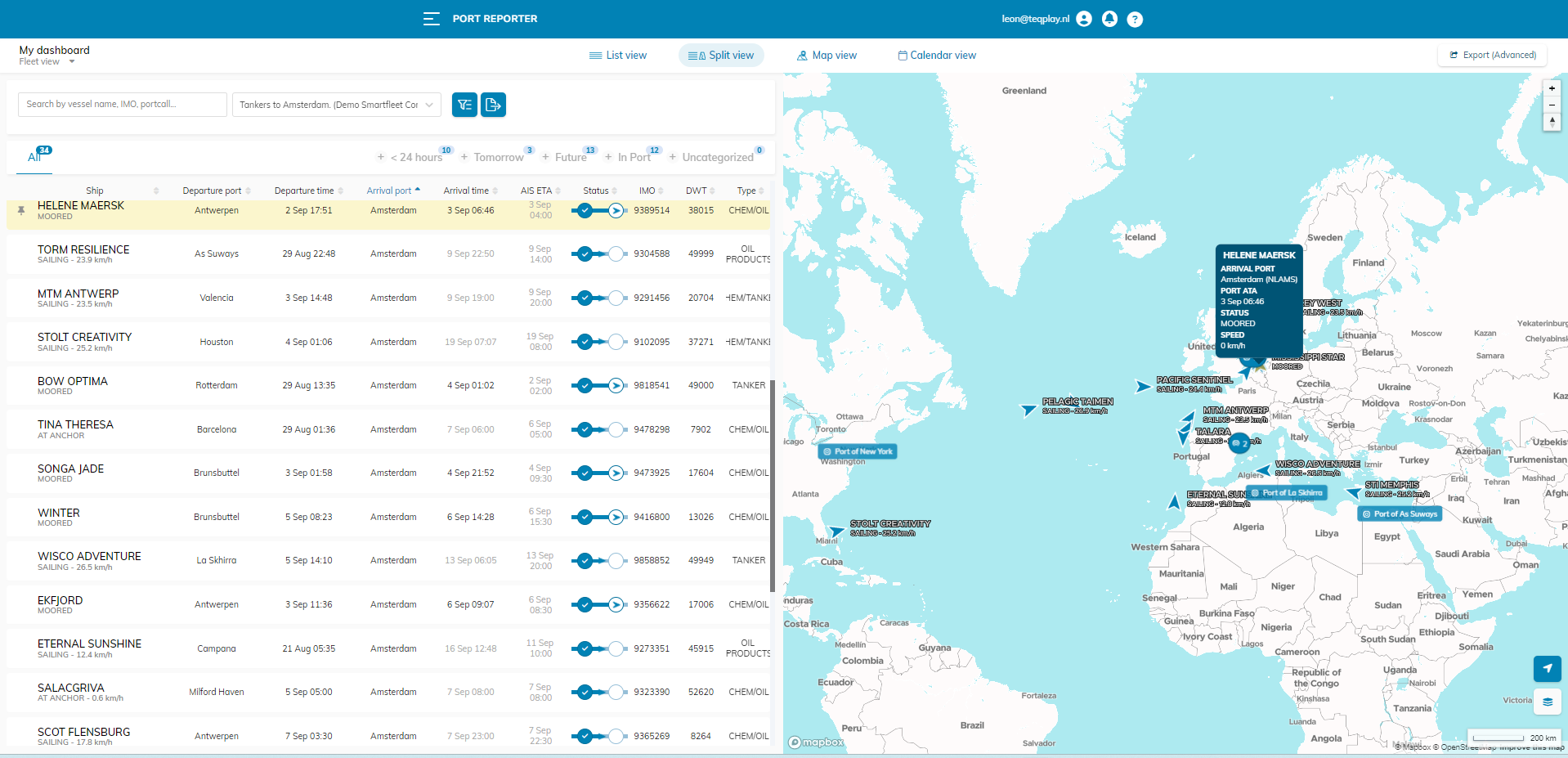

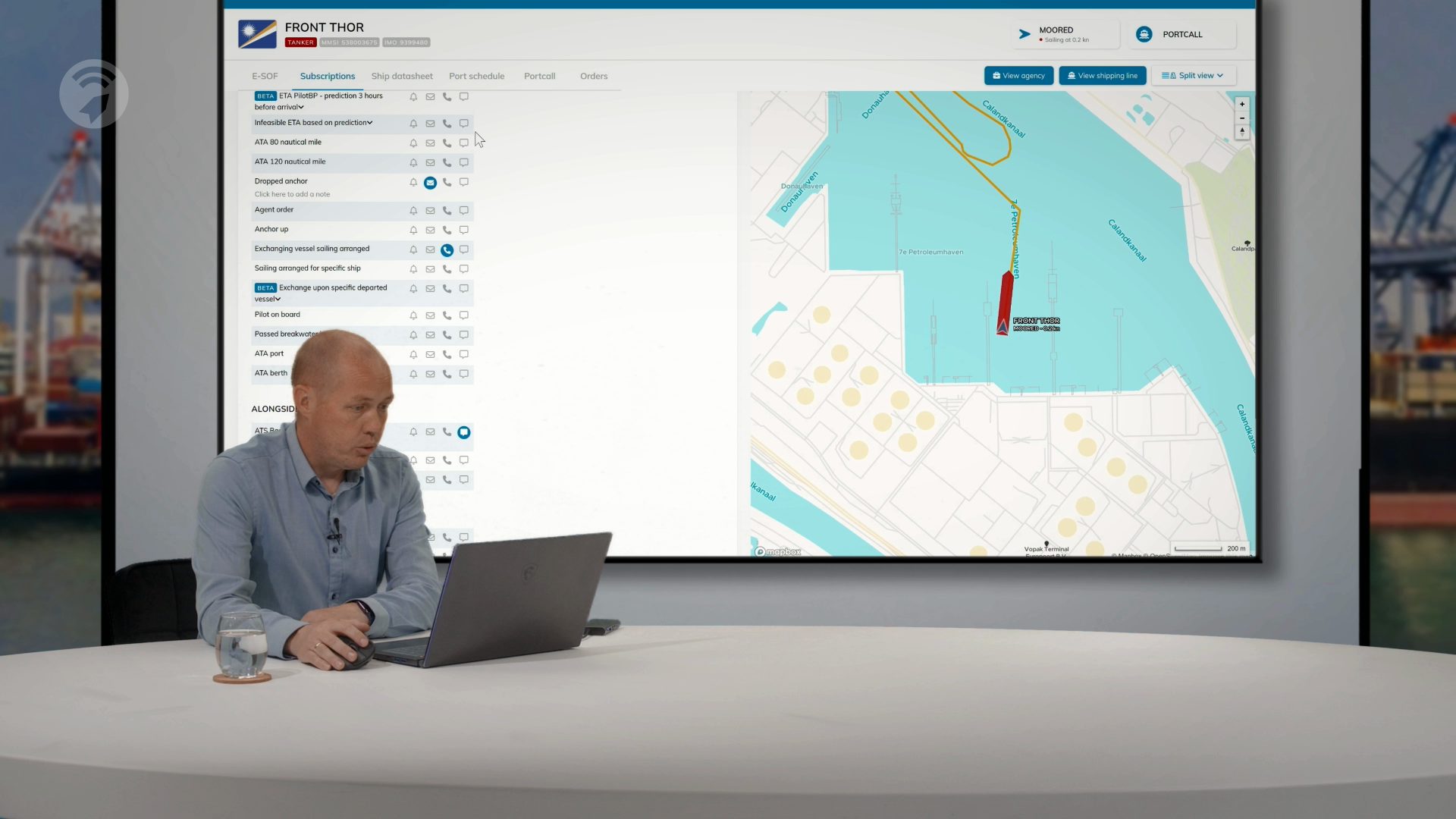

As an experienced player in the maritime world, Teqplay’s mission is port call optimization. However, as we continue our journey in providing the best solutions to optimize maritime operations, we came to understand that optimization is not just about the port call, but really about the movement of cargo on the vessel, from land port(s) to discharge port(s).

Why port call is not all there is

Since the port is the center of maritime operations, it is easy to tunnel your focus into a singular port call when planning optimization strategies. While the port is key to maritime activities, if we only look at port calls, we will not have the context necessary to fully understand the scale of the cost and time wasted. The ‘what’ and ‘why’ behind port times and port cost go beyond the port call. It is also about the movement of cargo and cargo flows.

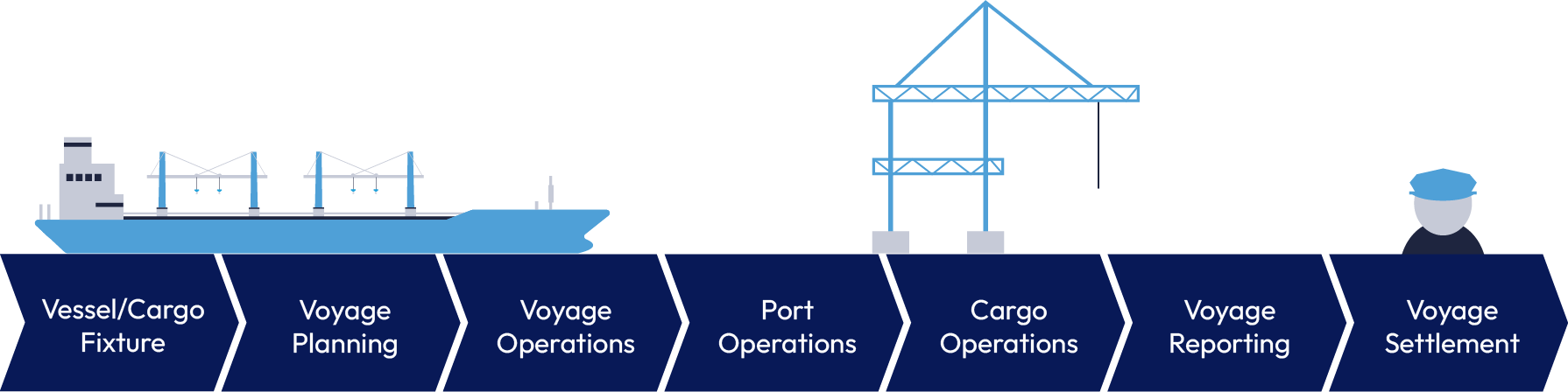

When we start thinking about maritime operations in the perspective of cargo movement, we are no longer constrained to single port calls. The cargo is not only in one port call, but it is being loaded at one (or more) ports and discharged at another (or multiple other) ports.

In short, in a cargo perspective, at least two port calls are always involved. Which means that in order to properly optimize operations, we need to zoom out and take a look at the bigger picture. Here, we can see the orchestration of the voyage, what happens at the load ports and discharge ports and all the activities in between. From there, we can start zooming into the details, taking a look at who the actors are and how they manage and coordinate everything.

It is this view that allows us the necessary context and details to make the right decisions. In the details in between the cargo movement process is where you start to notice a lot of waste and exposure to risk. With this perspective in mind, the challenge becomes uncovering and eliminating these waste and risk in cargo movement.

Expose & eliminate waste and risk

Challenges in optimizing port calls & cargo movement

The cost of moving cargo is high, largely due to waste that is often overlooked and accepted as just a part of business costs. Many maritime companies fail to grasp the full extent of this waste, the intricacies of the processes involved, and the potential for significant cost savings. Neglecting to delve into the ‘what’ and ‘why’ behind port times and associated expenses leads to avoidable waste and risks.

The lack of visibility and transparency also contribute to the issues. Too often, key stakeholders have operated in the dark in regards to the waste that occurs within the port when loading and discharging cargo. This lack of visibility has enabled an environment prone to conflicts of interest, compliance challenges, and substantial losses in terms of time, money, and emissions.

Within this context, there exists a significant amount of “hidden” time and cost. In essence, less efficient cargo movement allows some stakeholders to make more profit, perpetuating a detrimental cycle of inefficiency.

Why there is a lack of visibility

Moving cargo is already a highly complex process involving dozens of parties. This complicated process then unfolds within an environment characterized by lack of transparency, manual data entry, limited technological infrastructure, and a predominantly reactive approach. There is a lot of reliance on third-party involvement, as well as misinformation from multiple conflicting sources of truth. Furthermore, communication predominantly relies on traditional methods such as emails and phone calls, leading to data duplication and increased errors, making it difficult to effectively mine valuable information.

The cargo movement process

Implementing change to expose & eliminate waste and risk

Despite all the issues plaguing the industry, true change is difficult to achieve. For stakeholders, it is easy to see change as a disruption to an established process. As long as profits are still being made, hidden costs are just accepted, with a kind of “if it isn’t broken, why fix it?” mentality.

This is where Teqplay comes in to expose and highlight the importance of understanding these costs and the risks behind them. It is unsustainable to remain unchanged as the industry evolves, and embracing innovation is how companies gain a competitive edge.

Addressing the issues mentioned not only requires good solutions, but also good communication. All changes need to begin with explaining the ‘why’ behind them to the individuals involved. Some might worry that implementing new ideas reveals past shortcomings. However, adopting innovative solutions is, in fact, an opportunity to be a hero within one’s organization. It’s not about past mistakes; it’s about embracing a better future.

Léon Gommans | CEO/Co Founder of Teqplay

A serial entrepreneur who’s passionate about #innovation, #technology, #collaboration, and of course, #maritime. The mission is: to connect the dots & to get it to work, together with the industry!

- +31 (0)6 55306660

- leon@teqplay.com

- Léon Gommans

Frequently Asked Questions (FAQ)

The cost of moving cargo is high, largely due to waste that is often overlooked and accepted as just a part of business costs. Moving cargo is already a highly complex process involving dozens of parties. This complicated process then unfolds within an environment characterized by lack of transparency, manual data entry, limited technological infrastructure, and a predominantly reactive approach. More often than not, key stakeholders have to operate in the dark in regards to the waste that occurs within the port when loading and discharging cargo.

The first step to improvement is understanding. With a thorough examination of your processes by maritime experts with data-driven methodology, you can get a clear view of the issues. Once waste is exposed, we can identify its roots cause and pinpoint waste areas. The final phase involved implementation of sustainable solutions and set up KPIs that align with insights we have gathered, ultimately eliminating waste & risk in your port turnaround time.