The concept of digital twin was first coined by NASA, and became popularized in the aerospace industry. As a technology, digital twin is the result of continual refinement in engineering of the modern time. In the past decade, digital twin solutions have picked up traction in the maritime industry and quickly become an important talking point for maritime innovators.

The digital twin represents real world conditions and processes. It is not just a simulation, but also a tool that helps stakeholders find the most optimal solution in real-time. The digital twin serves practical purposes in monitoring, maintenance, and testing integration. With mathematical precision and responsiveness to changes, the digital twin is the key toward a future of AI support that helps minimize human errors.

In order to build a successful digital twin, the maritime industry will need advances in certain areas:

1. World Model

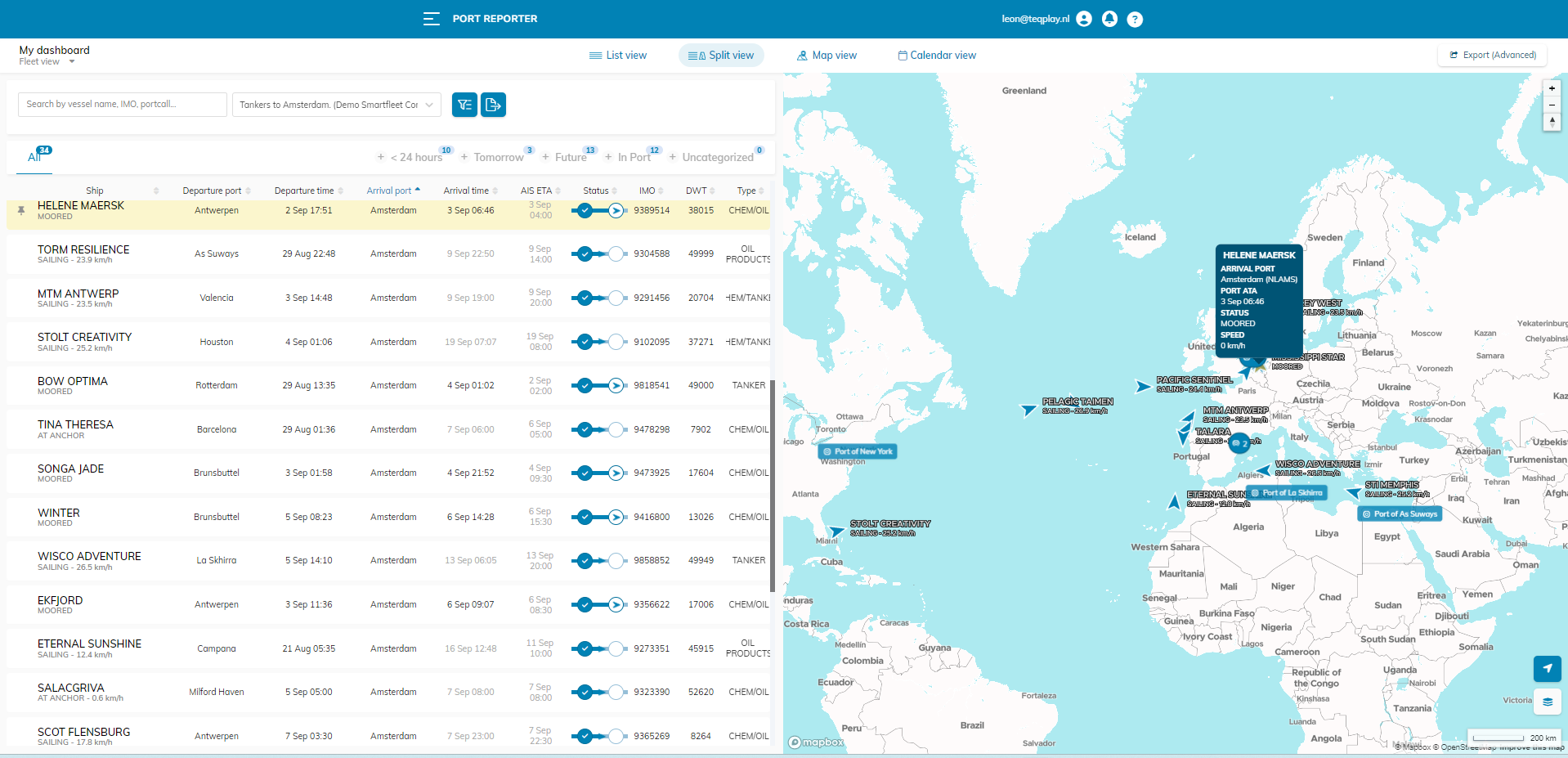

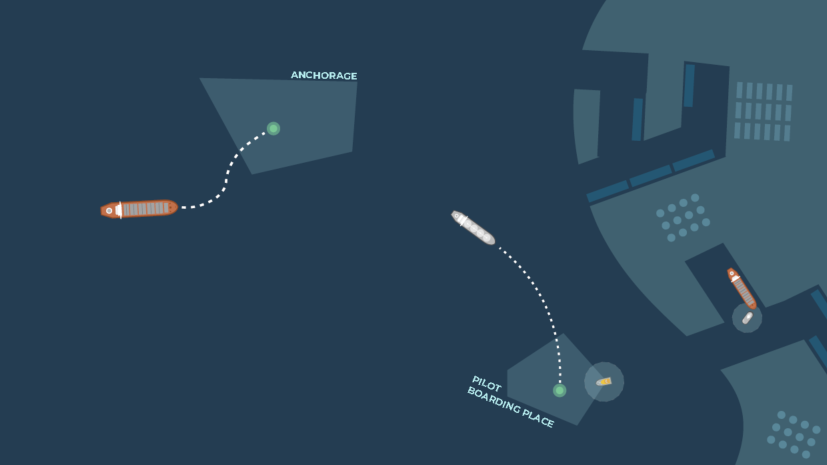

Digital twins need to reflect maritime processes. This requires detailed understanding and mapping of port calls and supply chains. Real-time update is an important aspect of a digital twin, which needs precision and accurate information to provide values.

2. Context Awareness

Once the model is created, it needs to be connected to the real world, requiring:

- IoT: necessary for data acquisition and real-time simulation of interactions between systems. In the future, a standardized industrial IoT system will allow the creation of a digital twin on a more global scale. Note: AIS is also considered IoT

- Cloud computing: computational power is an important foundation for creating a digital twin. As processes become more complex and the digital twin expands to encompass more parts of the maritime supply chain, improving both the power and security of cloud computing infrastructure is a must.

3. Decision Making

The goal of digital twin solutions is to provide stakeholders with the right context to make the most informed decisions. Improving decision support capabilities also require:

- Machine learning: a good digital twin needs to be capable of self-improvement. Automating processes and mitigating human errors are also the key benefits of machine learning and digital twin solutions.

- AI: it is important to ensure unbiased AI implementation to create trustworthy output. A good AI also provides systems with better predictive capabilities, reducing risks of disruptions, delays, and congestion.

Digitalization progress is inevitable across every sector in the supply chain, and maritime businesses will need to quickly adapt to this future. An important step is to understand the value of building a digital twin and how to create a competitive advantage from this solution.

Mai Zaki | Account Manager at Teqplay

Passionate about #portcall, #supplychain, #optimization, #digitalinsights, and the #maritimeindustry.

- +31 (0)6 20478530

- mai@teqplay.com

- Mai Zaki