What is the maritime supply chain?

The maritime supply chain involves the movement of goods and materials by sea and inland waterways from one place to another. The sea, the hinterland and its inland waterways, as well as the port are the main links that connect the maritime supply chain. In order to ensure a smooth sailing future for the industry, it is important to understand what the supply chain involves, what might disrupt it, and how it can be improved.

1. The sea

The sea plays a central role in the maritime supply chain, as it is the primary mode of transportation for goods that are shipped internationally. The movement of goods by sea and waterways is often the most cost-effective and efficient way to transport large volumes of cargo over long distances.

The shipping industry is therefore an essential component of the global economy, with thousands of ships transporting a wide range of goods, including consumer products, raw materials, and manufactured goods, between countries and continents.

However, the sea also poses risks and challenges for the maritime supply chain, including the potential for accidents, pirates, and other threats to the safety of ships and crew. There are also environmental concerns associated with shipping, including the emission of greenhouse gasses and the potential for oil spills and other pollution. The shipping industry is working to address these challenges through the development of cleaner technologies and more sustainable practices.

2. The hinterland

The hinterland is the land-based region that is served by a port. It refers to the area beyond the port and the immediate surrounding region, and includes the transportation networks and logistics hubs that connect the port to the rest of the country or region.

The hinterland is an important part of the maritime supply chain, as it plays a key role in the movement of goods between the port and their final destination. This may involve the use of rail, truck, barges or other modes of transportation to move goods from the port to warehouses, distribution centers, and other points of distribution within the hinterland.

The efficiency and effectiveness of the hinterland connection can have a significant impact on the overall performance of the supply chain. Factors that can affect the hinterland connection include the availability and quality of transportation infrastructure, the presence of efficient and effective logistics hubs, and the availability of skilled labor and other resources.

3. The port

A port can be thought of as a node in the maritime supply chain, as it is a critical point of connection between the sea and the hinterland. A port serves as a gateway for the movement of goods by sea, and plays a vital role in facilitating the flow of trade between countries and regions.

Ports are often located near major transportation hubs, such as airports and rail terminals, which allows for the seamless transfer of goods between different modes of transportation. This helps to ensure that goods can be efficiently moved from the port to their final destination within the hinterland.

Because of the port’s importance as the point of connection within the supply chain, optimizing port activities is highly prioritized. Understanding port call optimization is a necessity for port actors and relevant stakeholders, especially in this era of change and disruption for the maritime industry.

4. Networks

The maritime supply chain also includes several distinguished types of networks:

- Liner networks: These are regular, scheduled services that operate on a fixed route, with a set schedule for departures and arrivals. Liner networks are typically used to transport containerized cargo, and they can include many different ports of call along the route.

- Tramp networks: These are irregular, unscheduled services that do not operate on a fixed route or schedule. Tramp ships are chartered on a voyage-by-voyage basis, and they can call at any port that is able to handle the type of cargo they are carrying.

- Feeder networks: These are short-sea shipping services that connect smaller ports and terminals to larger hub ports. Feeder ships are typically smaller than container ships and are used to transport cargo between ports that are not served by liner networks.

- Shortsea shipping: This refers to the maritime transport of goods over short distances, usually within the same region or between neighboring countries. This type of shipping often uses smaller vessels, and can be considered as a part of the feeder networks.

- Coastal shipping: This refers to the maritime transport of goods along the coast, usually within the same country. This type of shipping often uses smaller vessels, and can be considered as a part of the feeder networks.

Each of these networks have their own characteristics, advantages and disadvantages and are used depending on the cargo, distance and the location. It is also worth noting that these networks are not mutually exclusive and can overlap in some cases.

What are the important metrics and KPIs?

KPIs are important for measuring the actual performance. KPI’s are essential for knowing the performance and for continuous improvement initiatives in the maritime industry. Data collection is key; thus digitization is key for improvement programs.

Each of the actors does have its own set of metrics or KPIs reflecting the specific role and activity of the actors.

Port:

- Throughput (number of TEUs, tonnage, etc.)

- Turnaround time (time for a vessel to complete port visit)

- Berth occupancy rate (percentage of berths occupied)

- Utilization rate (percentage of port capacity being used)

Terminal:

- Productivity (moves per hour, crane productivity, loading / discharge rates etc.)

- Equipment utilization (percentage of equipment being used)

- On-time delivery (percentage of cargo delivered on schedule)

- Space occupancy rate (percentage of terminal space occupied)

Shipping Lines:

- On-time performance (percentage of vessels arriving on schedule)

- Cargo volume & utilization rate (cargo capacity utilized, vessel in use)

- Turnaround time (berth and port turnaround time)

- Fuel Consumption & Emissions (cost of fuels, emissions)

- Revenue per TEU

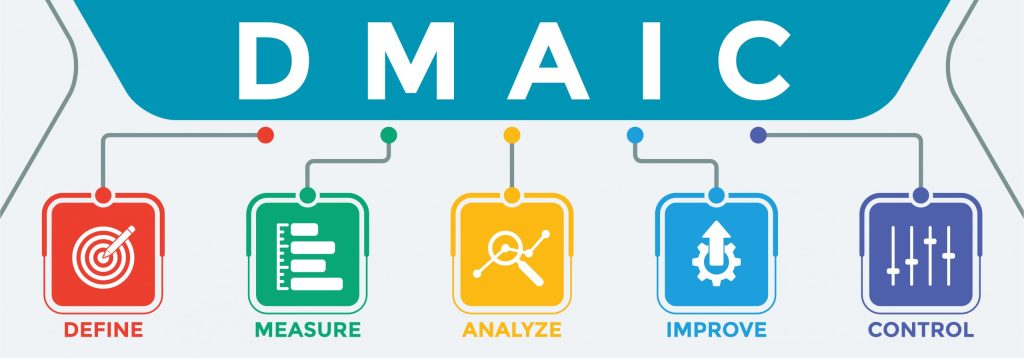

To remain in control of these important KPIs, one of the established methods of continuous improvement is DMAIC, a data-driven quality strategy used to improve processes. It is an integral part of a Six Sigma initiative, but in general can be implemented as a standalone quality improvement procedure or as part of other process improvement initiatives such as lean.

Why is digitization important?

Among all the ways the maritime supply chain can be enhanced, digitization is essential in setting the foundation for future improvements. In comparison to other sectors, the maritime industry has always been somewhat slower and reluctant to change. Congestions, rising protectionism, and stricter regulations are among the many troubles plaguing the maritime supply chain, requiring the industry to either adapt or flounder. In terms of assisting maritime businesses, the potential of digital solutions cannot be dismissed.

Digital systems can provide real-time visibility into the location and status of vessels, cargo, and other assets, enabling better planning and decision-making.

On top of that, it can also streamline various processes such as documentation, communication, and cargo handling, reducing the time and effort required to complete tasks. By automating manual processes and reducing the need for physical documentation and intermediaries, digitalization can help reduce costs and time wasted throughout the supply chain. In terms of security, quality digital systems can improve safety by providing a secure and tamper-proof record of transactions, and by enabling real-time tracking and monitoring of assets.

Digital tools can also facilitate better communication and collaboration among different stakeholders in the supply chain, including carriers, shippers, ports, and logistics providers. Collaboration is especially important in maintaining the flow of operations and processes, and the integration of digital solutions also requires strong coordination among stakeholders.

What is disrupting the supply chain?

The growing focus on sustainability is also causing disruptions, as companies seek to implement more environmentally-friendly solutions and technologies. This leads to changes in maritime practices as well as changes in customer’s expectations.

Black swans like the COVID-19 pandemic have been the biggest disruption in recent years, affecting global trade and causing delays in the movement of cargo, as well as increasing costs for the industry. Beside the pandemic, tensions among various countries and political instability have also strongly affected global trade and caused uncertainty in the movements of the maritime supply chain.

As digitalization becomes more common, cybersecurity threats, such as cyber attacks and data breaches, have become a bigger and bigger concern for the industry. Such threats can disrupt the flow of cargo and cause damage to reputation and financial losses. This is one of the reasons why investment in quality digital infrastructure is crucial.

Other than the aforementioned disruptions, natural disasters such as hurricanes, earthquakes, and tsunamis are also events that cause damage to ports and other infrastructure, as well as affect cargo flow. Improving visibility is necessary to ensure that the industry can weather such events without suffering big losses.

The various disruptions caused by an unprecedented event have led to an increase in costs for the industry, further emphasizing the importance of improving resilience and adaptive capability.

What are the trends in the maritime supply chain?

- Higher freight rates: In 2022, container freight rates increased 5 times in comparison to pre-pandemic levels. Dry bulk freight rates also increased due to the war in Ukraine and crisis in the supply chain. The shipping industry is becoming more and more volatile, and UNCTAD is recommending that maritime stakeholders invest more in port infrastructure, connectivity, and digitalization.

- Digitalization: The industry is moving on from more traditional methods to more innovative solutions. There is a growing trend towards the use of digital technologies in the maritime industry, including the use of digital platforms for communication, tracking, and documentation.

- Sustainability: There is increasing pressure on the maritime industry to reduce its environmental impact, including through the use of alternative fuels, the implementation of more efficient technologies, and the development of sustainable supply chain practices.

- Resilience: The maritime supply chain is subject to many types of disruptions. The search for resilience includes efforts to improve infrastructure, logistics and development of new technologies and strategies for risk management. Additionally, there is a growing emphasis on collaboration and coordination among stakeholders to ensure the supply chain can function smoothly in case of disruptions.

- Increased regulation: There is a trend towards increased regulation in the maritime industry, particularly with respect to issues such as environmental protection, safety, and labor standards. Ensuring compliance is also an important goal for maritime businesses.

- The rise of smart ports: There is a trend towards increasing investment in smart port logistics and technology, particularly in developing countries, as a way to reduce costs and improve supply chain efficiency.

Why is (real-time) visibility so relevant in the industry?

The maritime supply chain is an enormous network of organizations, people, activities, information, and resources involved in the movement of goods. The complexity of the maritime supply chain means that it has many processes that need to be monitored and controlled.

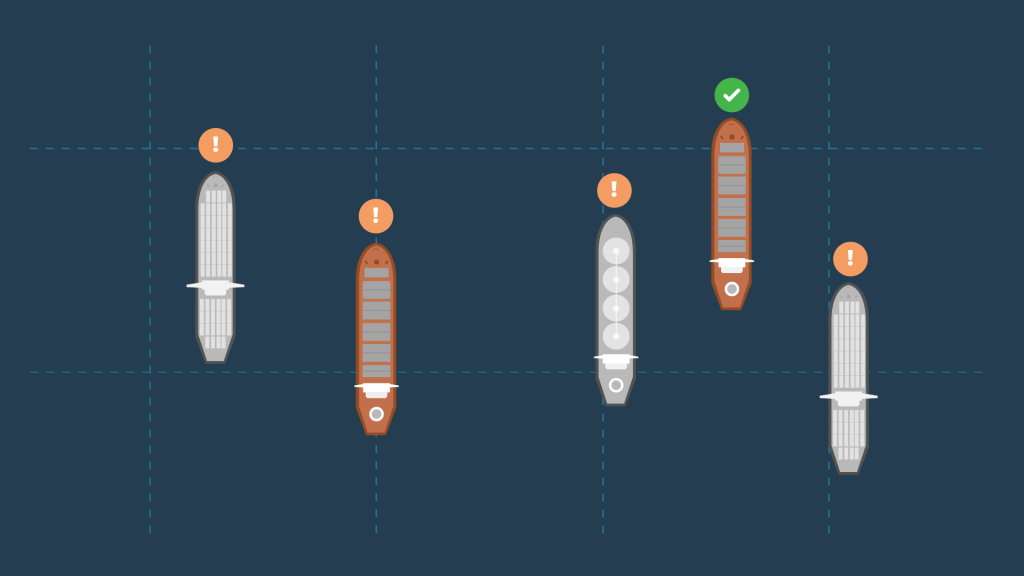

Strategically it is key to have visibility on the demand and supply, now and in the future for investment decisions. Visibility on the actual performance is essential, both to maximize the throughput and utilization, and to get the optimal price. Operational excellence is the king in this highly competitive maritime industry.

Meeting or exceeding the requirements at the minimal cost and no or limited environmental impact in a highly dynamic environment implies the need for state of the art decision making, and this requires getting the insights as quickly as possible to be able to adapt to the new risks or opportunities. In operations visibility translates into optimizing the scheduling and planning of the operations using all information that is available.

Documentation and customs clearance is another aspect that needs careful consideration. The preparation and submission of the necessary documents and paperwork is essential in facilitating the movement of goods across international borders, alongside customs declarations and other regulatory requirements. Lacking to address this issue will increase cost and lengthen the throughput.

Operational Excellence is the king, and in order to optimize and improve each step in the maritime supply chain, stakeholders need to have a clear understanding of what goes on in the supply chain, what needs to be improved, and the potential solutions.

What are the main pain points in the maritime supply chain?

Understanding the challenges present in the maritime supply chain is also crucial in the efforts to improve operational processes.

- Lack of transparency and visibility: It can be difficult to track and monitor the movement of goods across the supply chain, leading to inefficiencies and delays.

- High cost and complexity: The maritime supply chain can be expensive and complex, with many different stakeholders and intermediaries involved.

- Limited insight in available capacity: There is often a lack of visibility on the available shipping capacity, leading to higher costs and longer lead times for cargo.

- Regulatory and compliance issues: The maritime industry is subject to a wide range of regulations and compliance requirements, which can add complexity and cost to the supply chain.

- Risk of cargo loss or damage: There is always a risk of cargo loss or damage during transportation, which can have significant financial and operational impacts.

- Geopolitical risks: Political instability, trade disputes, and other geopolitical factors can disrupt the supply chain and affect the availability and cost of shipping services.

Valuable technologies

Technological advancements are important investments that have the potential to change the industry for the better.

1. Predictive analytics and big data

Thanks to analyzing data from large maritime systems, results about historical container patterns and ocean conditions can be obtained. Development in data analytics allows the industry to process data in real-time, efficiently track cargo, and stay up to date with on-going events to avoid costly mistakes. Over time, the data collected and analyzed can play an important role in redesigning ships, ports, and even maritime strategies.

2. Internet of Things

Internet of Things (IoT) implementation benefits smart linked vessels in many ways, including reducing fuel usage and maintenance expenses. IoT enables systems to communicate with one another in real-time to aid in process monitoring. Furthermore, this helps create a comprehensive picture of maritime operations and enable insight-driven decision making. Decisions will be based on actual performance as opposed to intuition or a set schedule. New status and events can be reported to relevant actors at the right time, contributing strongly to the detection of problems and saving costs.

3. Artificial Intelligence

AI is being integrated more in maritime technology. By removing tedious and repetitive procedures, AI has great potential to speed up and enhance the maritime industry. With machine learning and its capability in identifying patterns, together with big data, the industry will be able to build a truly formidable network of systems. When everything becomes interconnected, both internal and external, efficiency will increase drastically and human errors will be minimal.

4. Autonomous shipping

Relating to all of the aforementioned technologies, autonomous shipping is the end goal of maritime technological development. Autonomous systems have appeared among more developed ports, but true autonomous shipping remains scarce. An effective system that is less reliant on crew can both drive profits and reduce costs. At the moment, safety, legality and standardization are major obstacles in the application of autonomous shipping. That said, the rapid development of this innovation shows great potential for the future of the industry.

5. Digital Twin & Decision Support

The development of digital twin technology is a part of the overall digitalization trend in the maritime industry. The concept of digital twin is created to construct virtual replicas of complex physical systems. Activities within a port are also considered to be such complex systems, which gives rise to the need of digital twins to aid in decision making. Advances in simulation will allow digital twins to not only replicate the real world, but also predict its behavior. This will provide stakeholders with the most optimal options for their operations.

The power of a digital twin is its ability to put publicly available information into context. Ultimately, good decision making is all about having comprehensive and correct background information. The innovation of digital twin is a promising prospect in decision support for maritime businesses.

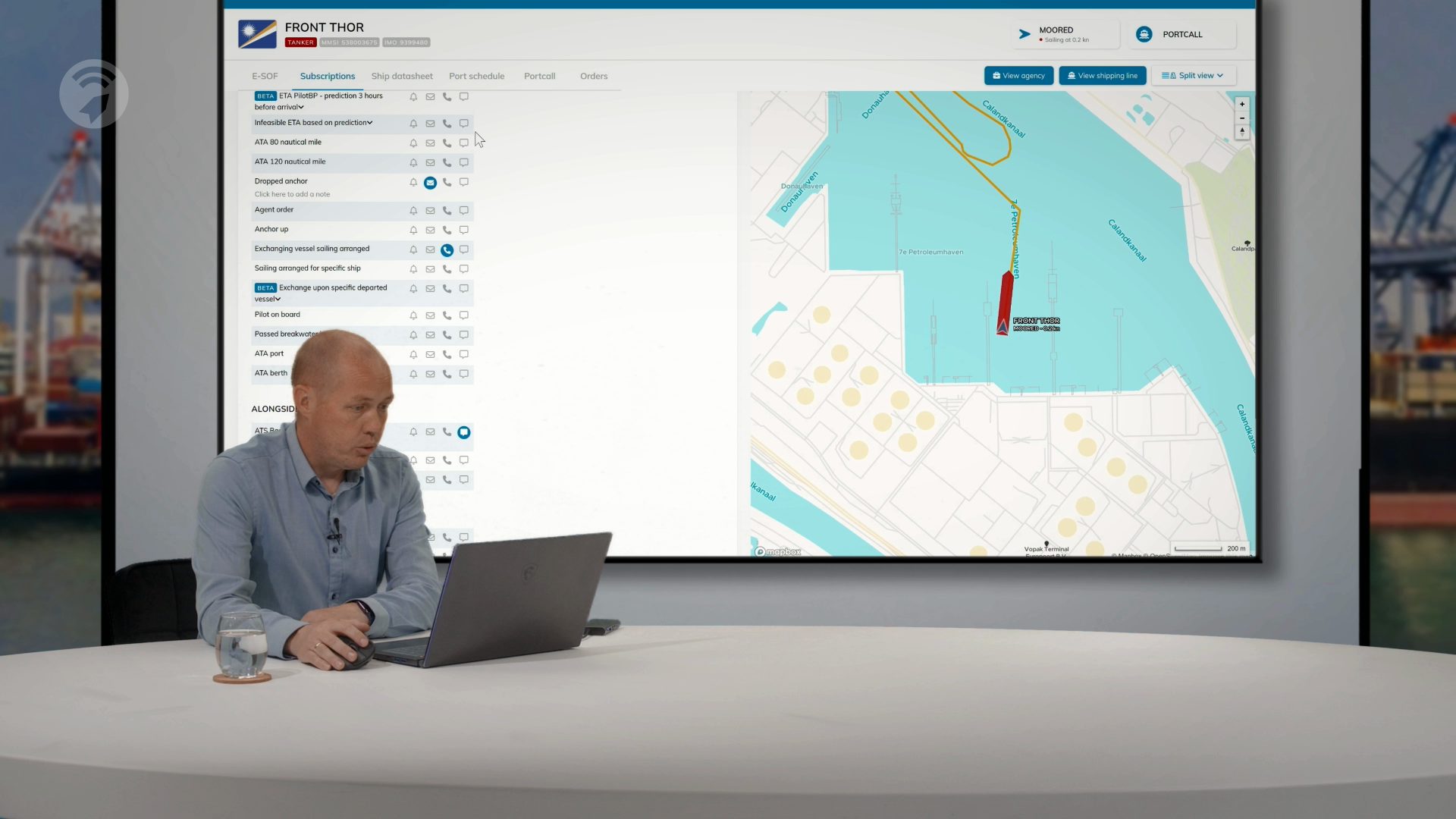

6. Integrated Control Systems

Maritime systems are becoming more interconnected, necessitating the creation of a control tower where actors can coordinate and monitor processes. Together with the digital twins, the control tower allows stakeholders to act upon the information they have and execute decisions in a timely manner. Such a control system is extremely helpful in maintaining performance, organizing documentation and ensuring awareness of important events for authorities and operators.

7. Robotics & Drones

The use of unmanned vehicles and robotic assistance has proven to increase cost efficiency and accuracy thanks to the mitigation of human errors. The development of robotics and drones help businesses acquire data even in the most hazardous environments and reduce the safety risks to personnel. The strength of robotic applications relies on the quality of telecommunication and data, requiring the industry to invest more into the development of these areas.

8. Augmented reality

Augmented reality (AR) is a useful advancement for both training and support of the maritime workforce. AR creates an overlay on top of the surrounding environment for users, allowing the simulation of situations and assisting in various tasks. High risk situations can be recreated to provide actors with important insights on what needs to be done without compromising safety. More integration of technology in maritime operations can be achieved with the application of AR.

Teqplay

In the modern development of the maritime supply chain, technology plays a crucial role. Tech firms such as Teqplay have taken on the mission to help the industry streamline processes, increase efficiency, and improve communication and collaboration.

Good planning and scheduling is crucial in determining the most efficient and cost-effective way to act. When moving goods by sea, important factors need to be considered, from the volume and type of cargo, the availability of shipping capacity, to the route and mode of transport. Along with those are negotiations and securitization of the necessary contracts and agreements with carriers, shippers, and other stakeholders in the supply chain.

Having the appropriate tools that can keep track of all necessary information is crucial in maintaining smooth operations. Through the use of digital tools, Teqplay can help the maritime industry gain actionable insights to gather important data, stay up-to-date with crucial developments, overcome challenges, and support decision making.

Download Teqplay’s Maritime Supply Chain white paper & more here

Léon Gommans | CEO/Co Founder of Teqplay

A serial entrepreneur who’s passionate about #innovation, #technology, #collaboration, and of course, #maritime. The mission is: to connect the dots & to get it to work, together with the industry!

- +31 (0)6 55306660

- leon@teqplay.com

- Léon Gommans