by Sander Jellema

During my holiday in France, I was able to feast on the delicacies the country has to offer.

I like to cook in my spare time and on the weekends, and trips like this give me new inspiration for cooking. Cooking is in many ways similar to the maritime supply chain. How? A number of things are essential for obtaining the best possible results. Think about timing, the right tools such as pans and knives and – of course – fresh ingredients.

Let’s look at timing tools and ingredients.

When I think of timing and cooking, I immediately think of my grandmother. It is enviable how she and many other women of that generation can cook by feel without using any kind of tools. But times change. I have her recipes in a notebook and yet I no longer get it right in terms of taste.The ingredients are the same, the tools are the same, but still it is not comparable. A painful observation is that the knowledge and experience built up over many years is not fully transferable. And the same happens within the maritime industry. The sense of timing, who does what and when, has deteriorated. Knowledge is not fully transferable and times change. If I may speak on behalf of generation X, it is mainly the timing that can no longer be based on gut feelings alone because the world has also changed. The conditions of contracts are much stricter than before, the visibility of the chain – including errors – has improved enormously and the introduction of the Internet and mobile communications has brought not only convenience but also higher expectations.

Tools, this is an interesting one. Contrary to our business philosophy, I believe that the core component of the tools we work with today hasn’t changed much compared to thirty years ago. This needs further explanation: I believe that it is human nature to absorb changes into the daily routine. Before the advent of mobile phones, data was exchanged over the landline, and people accepted it if you could not be reached. Mail by paper was replaced by fax, and people accepted that it could take a while for an answer. My point is that the ”functionality” of our tools has not changed much. Only the speed, and thus our acceptance has changed. But we haven’t changed the way we use tools. We still pass the same kind of messages, only faster. The real question is, if we have not changed, if the way we send messages has not changed, but the speed has increased significantly… Are we still able to remain as accurate as before? Or does the higher speed impose a pressure that leads to errors and, within the equation, occasionally causes the food to burn?

As a home cook, the most important thing for me is to work with fresh ingredients. These are the taste buds, one by one, and if you make concessions, the quality will suffer. Anyone who has ever seen the film”The Big Short” with Anthony Bourdain about making a seafood stew, may know where I am going with this. Like cooking, in the maritime industry it is important to work with fresh ”ingredients”: real-time data and insights.

OK, I’m a chef on a Sunday afternoon, setting the menu at a big restaurant. I ordered my fish on Friday, ….. But some of the fresh fish doesn’t sell. I don’t know why. Maybe it just came out halibut has the intelligence of a dolphin. So, what am I going to do? Throw all this unsold fish, ………, in the garbage, and take the loss? No way. Being the crafty and morally onerous chef that I am, whatever crappy levels of ….. I don’t sell, I throw into a seafood stew. See, it’s not old fish. It’s a whole new thing! And the best part is, they’re eating 3-day-old halibut….

Antony bourdain in “The Big Short”

The above is exactly what happens every day in maritime supply chain planning around the world.

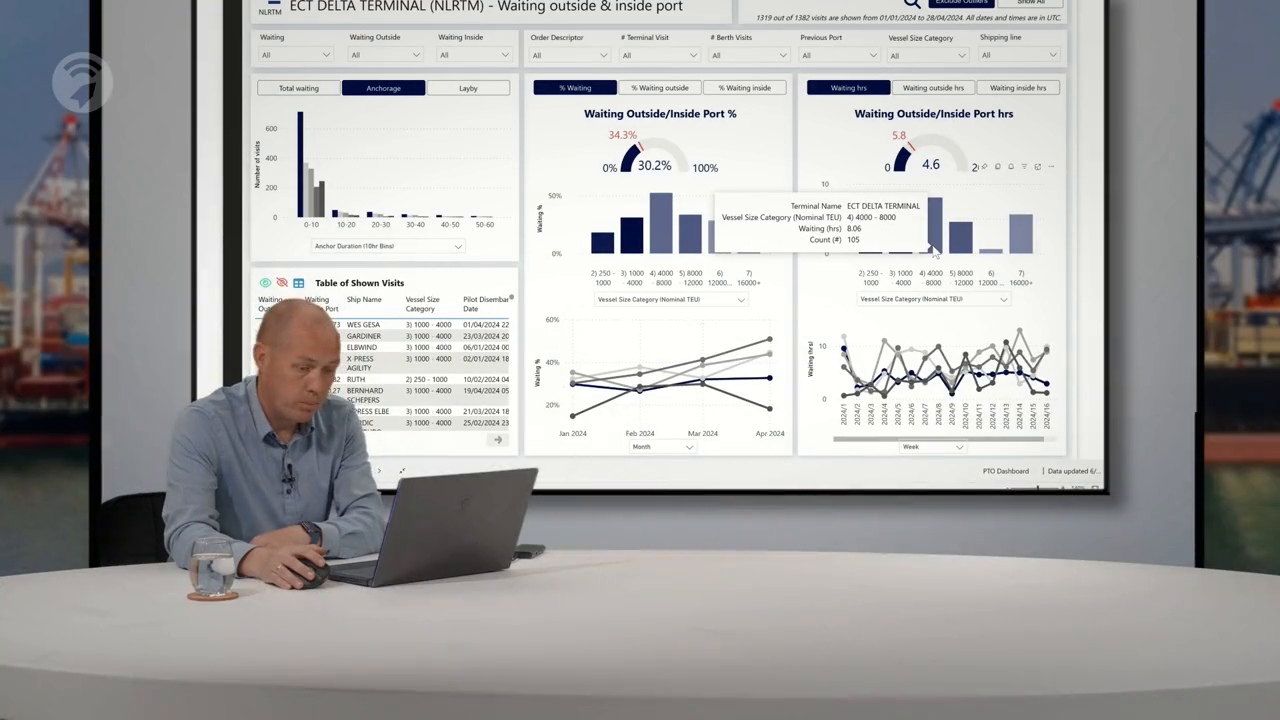

Data that we know in advance to be inaccurate is fed as ”ingredients” to internal systems and to other stakeholders. When we compile the results at the end of a quarter or year, we are then surprised again that we did not run optimally and did not achieve the best result. But, this only comes closer when you start working with the right ingredients; real-time data and improved insights. Some people then say, “we don’t use as much bad data and insights as Anthony Bourdain’s example, so that doesn’t apply to our organisation“.

Apparently, these people have a point, but I like to argue that one single bad data entry, or entering one bad ETA is equivalent to a clove of garlic. Yes, it is a small component, but you taste it throughout the whole dish.

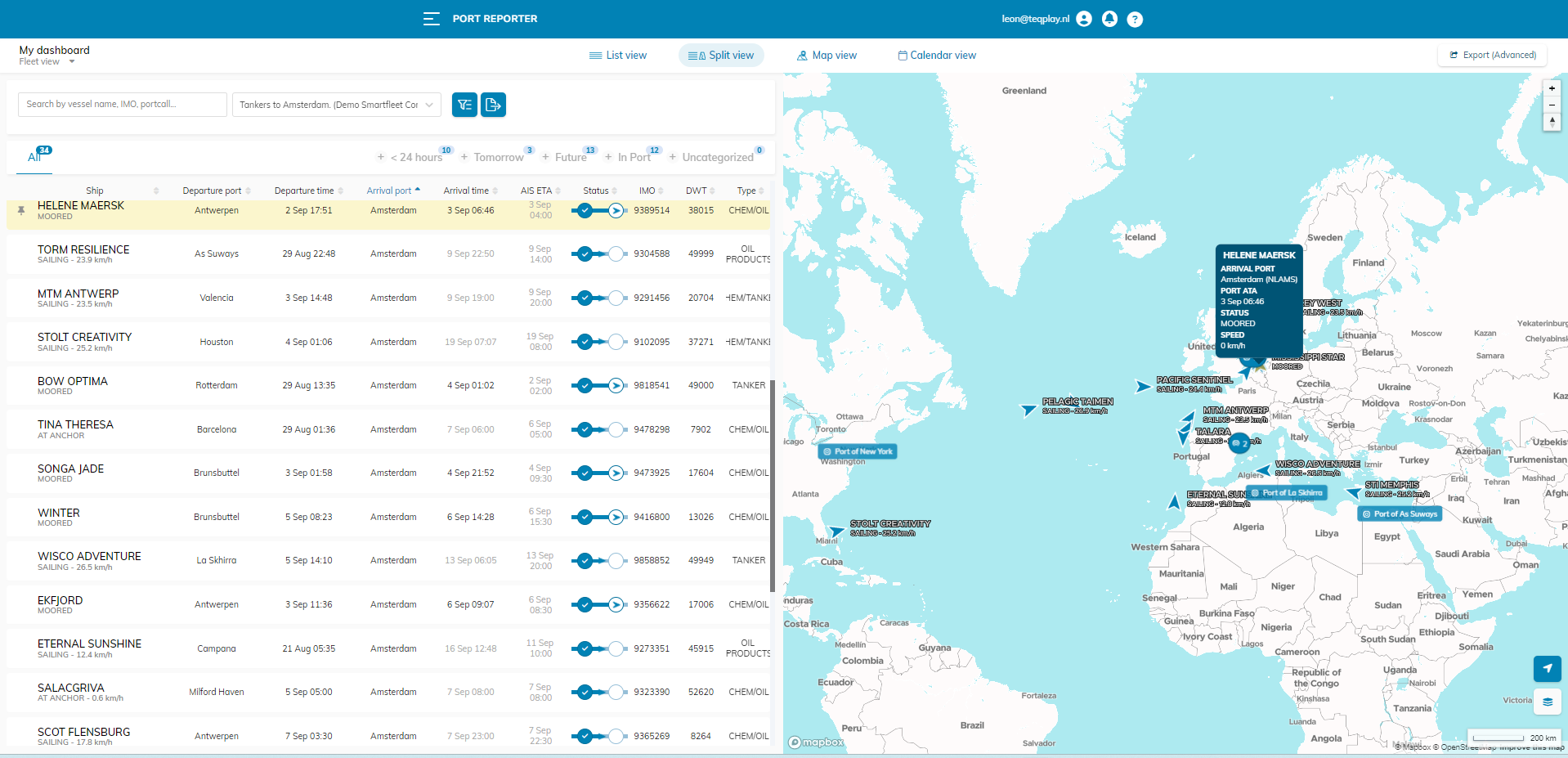

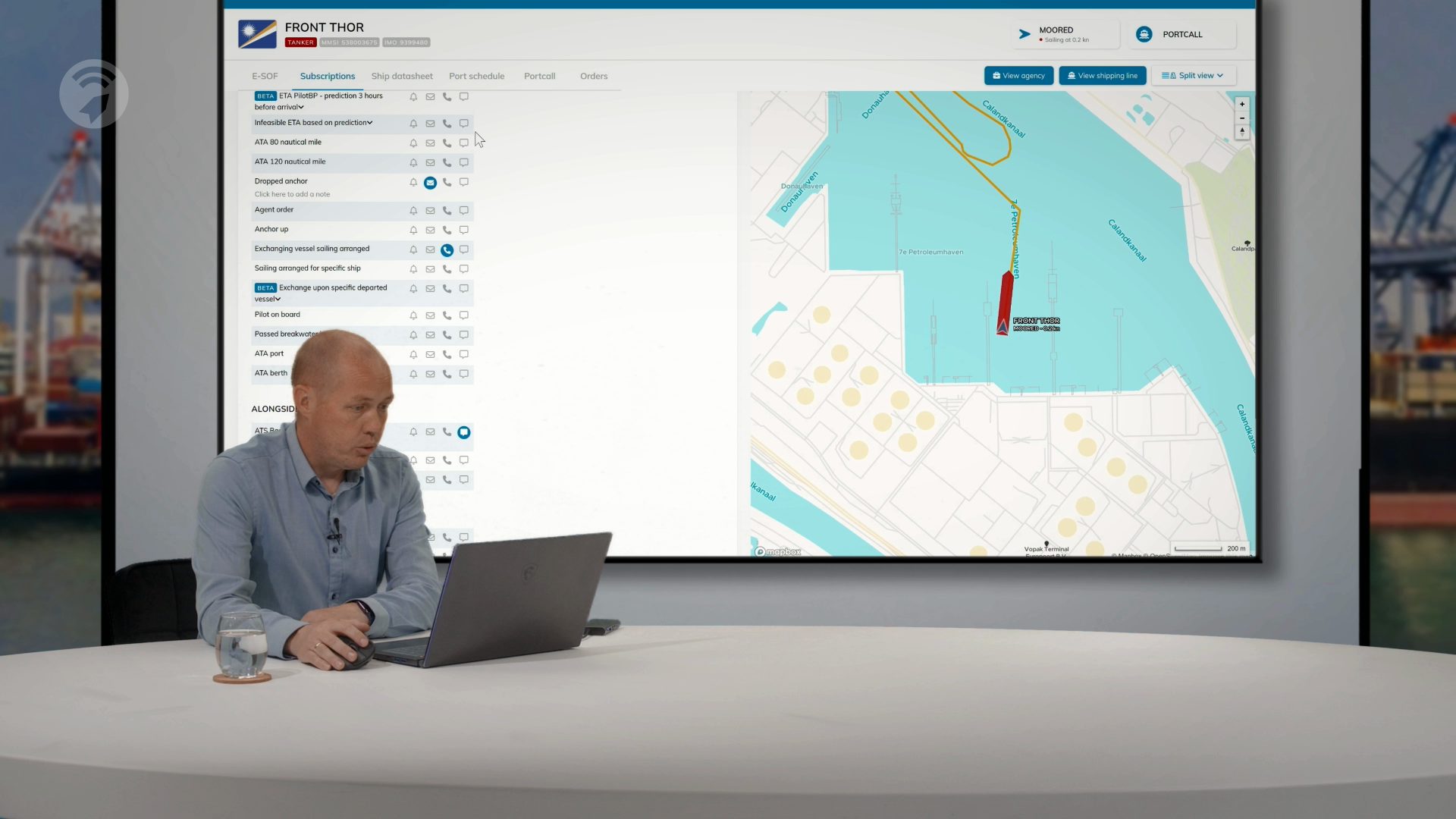

Of course, we have a clear vision of the interplay between timing, tools and ingredients. Within Teqplay we believe that a combination of the right data, artificial intelligence and the intrinsic will to do things even better together is the key to success. Together with our customers, we have proven that this approach works, and we have reduced port calls by an average of two hours.

Are you curious how, or would you like to join us for dinner? You’re invited!

Teqplay – connecting the dots

Attributes:

“Top view, weighing beet leaves on kitchen scale, concept of calorie intake and drawing up menu for diet” by Marco Verch Professional Photographer is licensed under Attribution 2.0 Generic (CC BY 2.0) No changes were made.

“Grandma’s Oatmeal Cookie Recipe” by Chiot’s Run is licensed under Attribution-NonCommercial 2.0 Generic (CC BY-NC 2.0) No changes were made.

Fresh_Vegetables by mahmoud99725 is licensed under Attribution-ShareAlike 2.0 Generic (CC BY-SA 2.0). No changes were made.