- Unlock the power of real-time data and predictive capability with digital twin technology.

- Learn how ports and terminals can optimize performance, improve safety, and reduce environmental impact by using digital twins to monitor and visualize real-time data in a comprehensive way.

- Discover the benefits of digital twin and how it can support situational awareness and decision making in the maritime industry.

What is a digital twin?

A digital twin is a virtual replica of a physical asset or system that can be used for simulation, analysis, and monitoring. The first practical application of digital twin technology was developed by NASA, and the technology has also gained a reputation in the maritime industry.

Digital twins are mathematical models based on real-time data and are used to represent the current or past state of a system. The biggest strengths of a digital twin are its predictive capability and the ability to self-improve. While a normal simulation can answer what-if questions, digital twins go one step further and give the answer to the question: if that happens, what is the optimal decision?

Port call optimization with digital twin

Ports and terminals are complex entities, and optimizing them requires flexible integration of processes and networks. Operations in the supply chain are always interconnected and continuous, and having a tool that makes use of real-time data like the digital twin is a good way to remain in control for port actors.

Digital twins can also be used to monitor the performance of an asset in real-time, enabling port actors to identify and address issues before they become major problems. This can help improve safety and reduce downtime, as well as enabling more proactive planning. In addition to optimizing performance and improving safety, digital twins can also help to reduce the environmental impact of port operations. By identifying the most environmentally friendly options, digital twins help minimize the carbon footprint of processes by optimizing them.

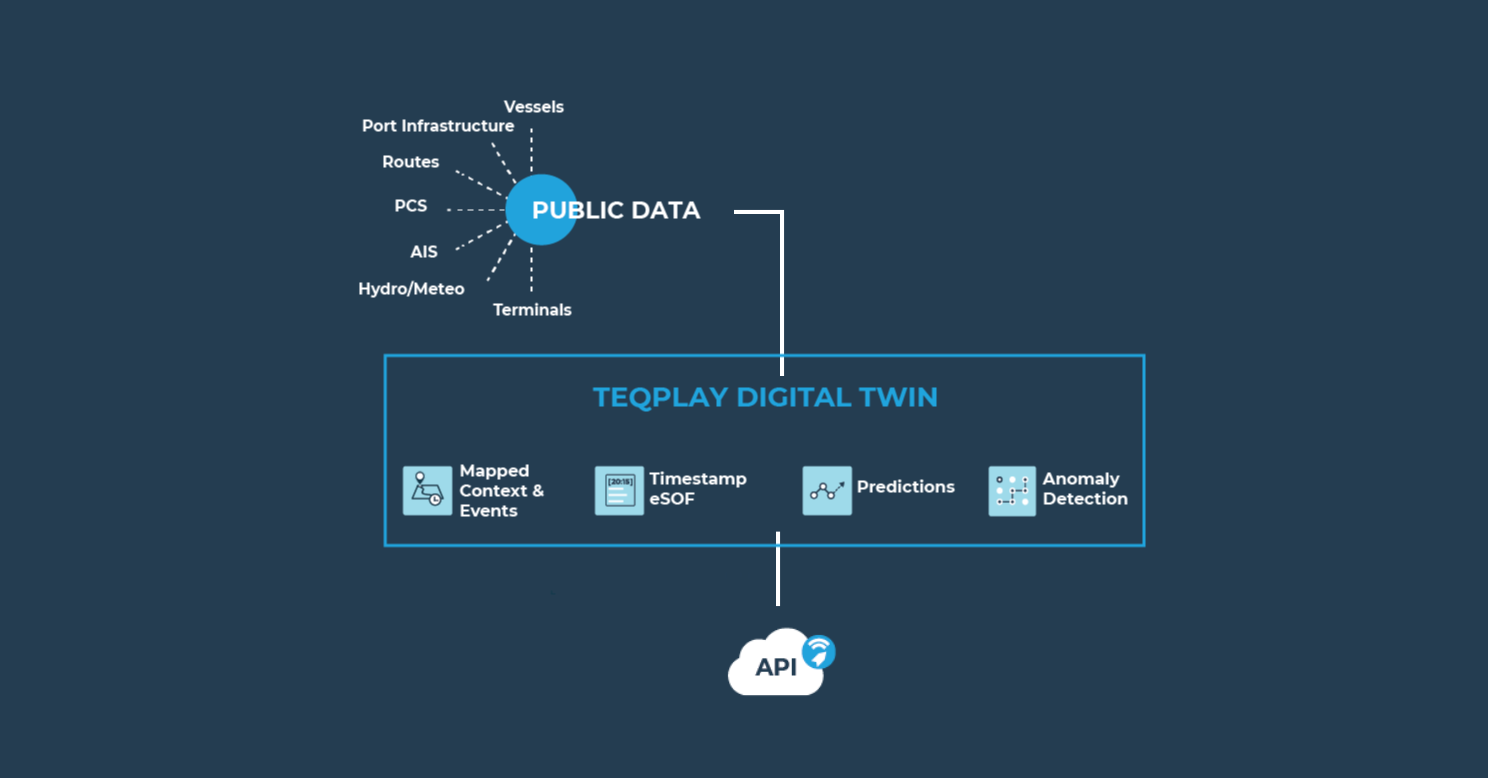

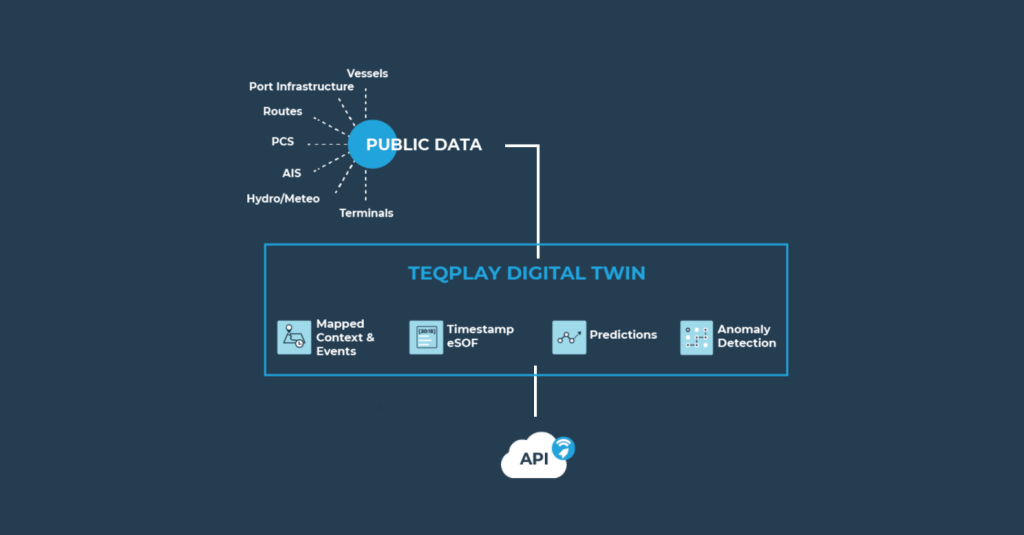

Digital twins can also support situational awareness by enabling the integration of data from multiple sources. This data can be used to create a comprehensive view of vessels’ position, speed, heading, and other key parameters, as well as the surrounding environment. With such accurate real-time information, ports and terminals can more easily manage and remain in control of events in and around the port areas.

In addition to providing real-time data, digital twins can also be used to visualize the data in a way that is easy for operators to understand. For example, a digital twin could be used to display a 3D model of the vessel and its surroundings, with data overlaid to show the position and movement of the vessel, as well as other important information such as weather conditions, traffic, and hazards.

By providing a comprehensive and real-time view of the vessel and its surroundings, digital twins enable port actors to make more informed decisions and respond quickly to changing conditions. With its potential, digital twin technology has become an important investment for maritime businesses looking for innovative optimization solutions.

Teqplay

The potential benefits of digital twins in the maritime industry are significant, and many companies are investing in the development and deployment of digital twins to optimize the design, construction, operation, and maintenance of ships, ports, and offshore structures. Teqplay is also a strong advocate for the development of digital twins for the sake of port call optimization. As an experienced player in the maritime industry and developers of digital solutions, we believe that building a digital twin is an essential step toward a better future for the industry.

Léon Gommans | CEO/Co Founder of Teqplay

A serial entrepreneur who’s passionate about #innovation, #technology, #collaboration, and of course, #maritime. The mission is: to connect the dots & to get it to work, together with the industry!

- +31 (0)6 55306660

- leon@teqplay.com

- Léon Gommans