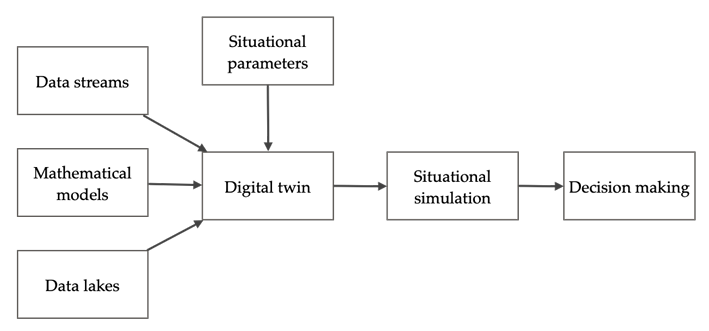

What is a digital twin?

A digital twin is a virtual replica of a physical asset or system that can be used for simulation, analysis, and monitoring. In the maritime industry, digital twins can be used to optimize the design, construction, operation, and maintenance of ships, ports, and offshore structures. The biggest strengths of a digital twin are its predictive capability and the ability to self-improve.

Digital twins are mathematical models based on real-time data and are used to represent the current or past state of a system. In comparison, a traditional simulation is used to predict the future behavior of a system based on a set of assumptions and inputs. While a normal simulation can answer what-if questions, digital twins go one step further and give the answer to the question: if that happens, what is the optimal decision?

Maritime use cases for digital twin

1. Fleet optimization

One of the main benefits of digital twins in the maritime industry is the ability to predict and optimize performance. By simulating the behavior of a vessel or structure in different operating conditions, it is possible to identify potential issues and optimize the design and operation to improve efficiency and reduce costs. Using both historical and on-going data, a digital twin can serve as the basis for important decisions concerning fleets’ operations and management.

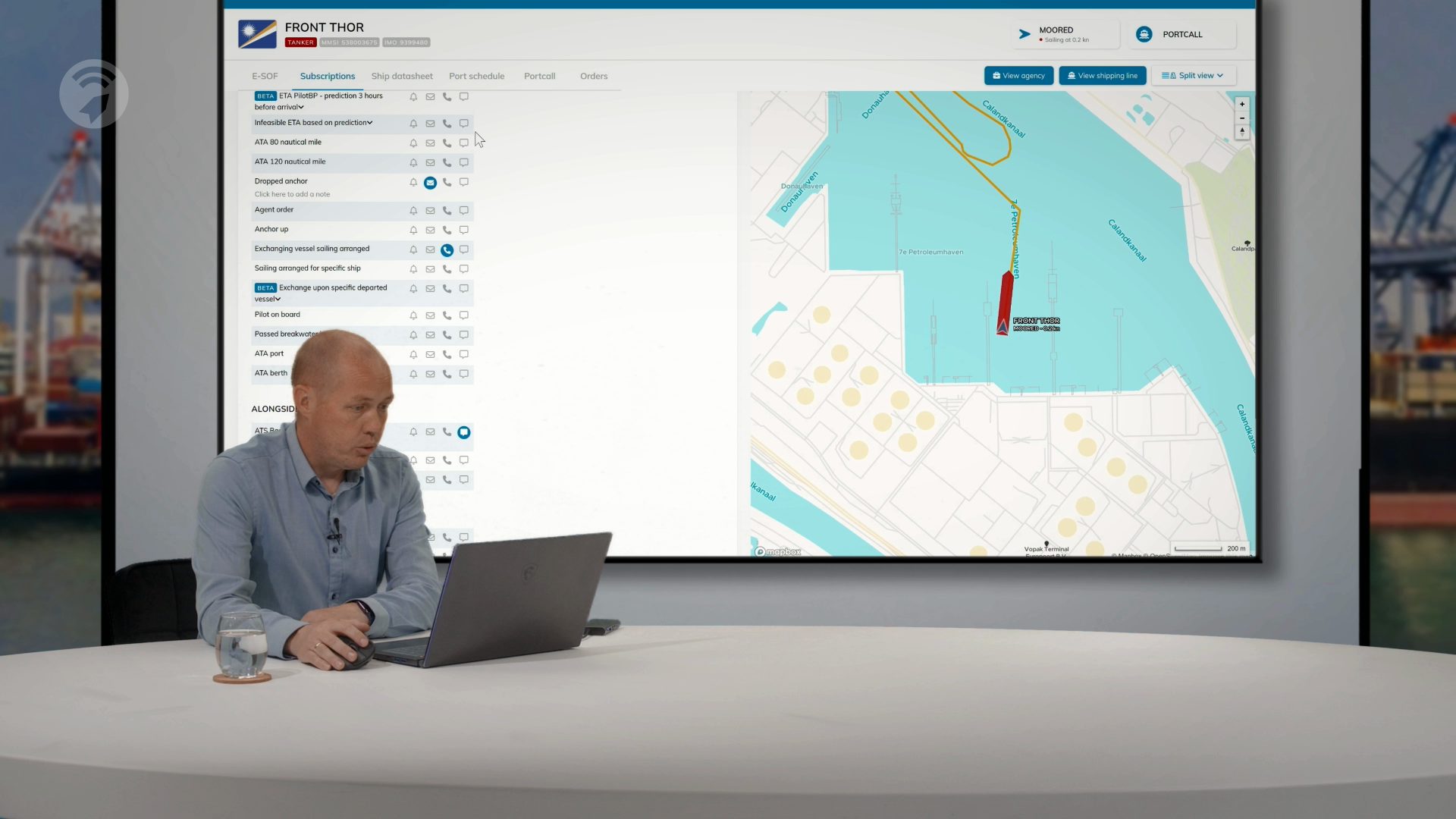

2. Terminal and port call optimization

Ports and terminals are complex entities, and optimizing them requires flexible integration of processes and networks. Operations in the supply chain are always interconnected and continuous, and having a tool that makes use of real-time data like the digital twin is a good way to remain in control for port actors.

Digital twins can also be used to monitor the performance of an asset in real-time, enabling operators to identify and address issues before they become major problems. This can help to improve safety and reduce downtime, as well as enabling more proactive maintenance and repair schedules. In addition to optimizing performance and improving safety, digital twins can also help to reduce the environmental impact of maritime operations. By identifying the most environmentally friendly options, digital twins help minimize the carbon footprint of ships and offshore structures.

3. Situational awareness

Digital twins can support situational awareness by enabling the integration of data from multiple sources, including sensors, navigation systems, and other equipment on the vessel. This data can be used to create a comprehensive view of the vessel’s position, speed, heading, and other key parameters, as well as the surrounding environment.

In addition to providing real-time data, digital twins can also be used to visualize the data in a way that is easy for operators to understand. For example, a digital twin could be used to visualize the vessel and its surroundings, with data overlaid to show the position and movement of the vessel, as well as other important information such as weather conditions, traffic, and hazards.

Overall, digital twins can help to improve situational awareness by providing a comprehensive and real-time view of the vessel and its surroundings, enabling operators to make more informed decisions and respond quickly to changing conditions.

The challenges of implementing digital twins

1. Data availability and quality

In order to create an accurate digital twin, it is necessary to have access to high-quality data from multiple sources. However, in the maritime industry, low data availability has always been a problem that hinders the development of digital solutions. Additionally, the data may be of variable quality, depending on the age and condition of the equipment used to collect it, which is an additional difficulty.

2. Integration of systems and data

Another challenge is integrating the data from different sources into a single, cohesive view of the vessel or asset. This requires the development of robust and scalable data management systems that can handle the large volumes of data generated by modern ships and offshore structures.

3. Regulatory and security issues

The maritime industry is subject to a range of regulatory and security requirements, which can impact the development and use of digital twins. For example, there may be restrictions on the types of data that can be collected or shared, or requirements for data to be stored and transmitted in a secure manner.

4. Cost and resources

Implementing digital twins in the maritime industry can be a complex and resource-intensive process, requiring the development of new systems and infrastructure, as well as the training of personnel. Computational power is also a major concern, requiring investment into cloud computing in order to support digital infrastructures and data storing. This can involve significant upfront costs and require ongoing investment in order to maintain and update the digital twin over time.

Despite these challenges, the potential benefits of digital twins in the maritime industry are significant, and many companies are investing in the development and deployment of digital twins to optimize the design, construction, operation, and maintenance of ships, ports, and offshore structures.

Teqplay is also a strong advocate for the development of digital twins in the maritime industry. As an experienced player in the maritime industry and developers of digital solutions, we believe that building a digital twin is an essential step toward a better future for the industry

Léon Gommans | CEO/Co Founder of Teqplay

A serial entrepreneur who’s passionate about #innovation, #technology, #collaboration, and of course, #maritime. The mission is: to connect the dots & to get it to work, together with the industry!

- +31 (0)6 55306660

- leon@teqplay.com

- Léon Gommans