From Yara: The importance of effective planning and optimization tools in operations

In the presentation from Yara in Navigate 2024, Tom Tissink, Logistics & Loading Manager at Yara Sluiskil presented the increasing complexity in the planning processes as production evolves. Tom delved into the challenges posed by high key occupancy, and highlighted the crucial roles of effective optimization tools.

Tom first reiterated Yara’s mission of responsibly feeding the world while protecting the planet. With half of the world’s population relying on food grown with mineral fertilizer, the importance of fertilizers in global food production cannot be overstated. However, he also acknowledged the environmental challenges associated with fertilizer production.

Despite the necessity of fertilizers , the production process inevitably leads to significant levels of emissions. Tom then introduced Yara’s approach to mitigate these emissions through the production of blue ammonia. By capturing and liquefying CO2 emitted during ammonia production, Yara aims to reduce its environmental footprint. This initiative aligns with Yara’s commitment to sustainability and demonstrates the company’s proactive stance towards environmental responsibility.

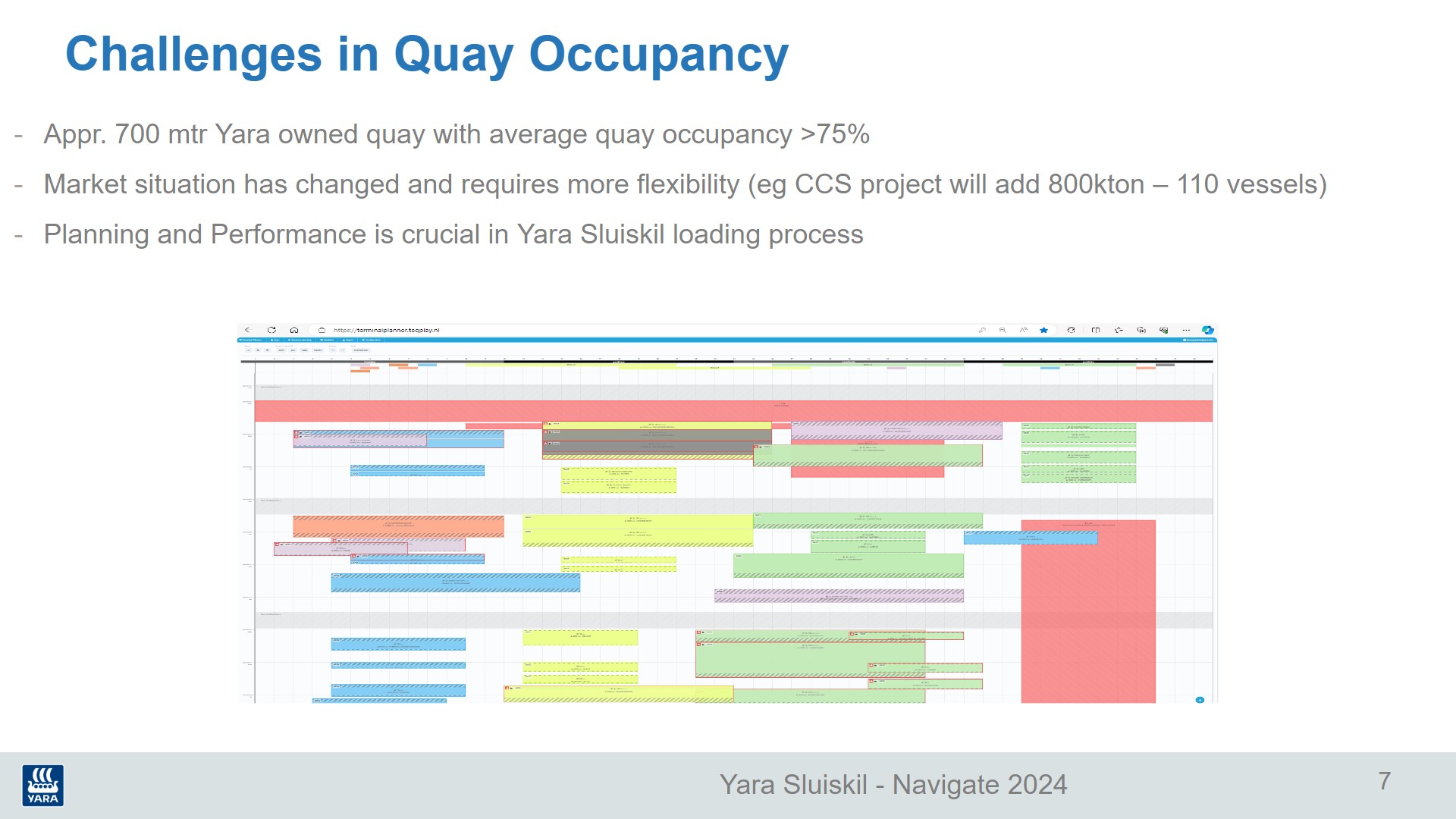

However, with the change in production, it became a huge and demanding challenge for Yara to maintain optimal planning and performance. As occupancy levels become higher and higher, it is more important than ever for Yara to have an innovative solution that ensure on-time vessel arrivals and loading of products.

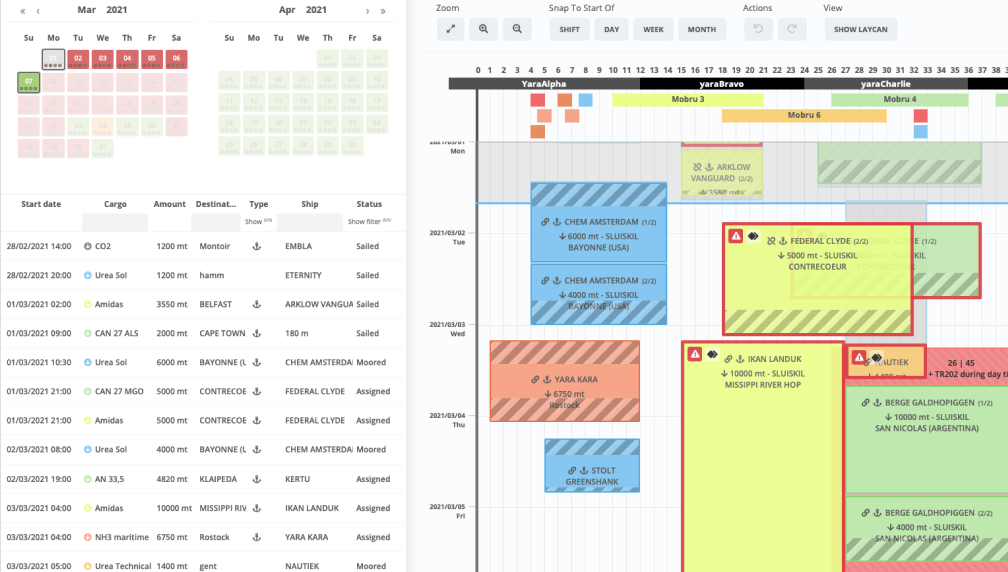

As a critical hub for loading, meticulous planning and efficient execution is a must for Yara Sluiskil. To address these challenges, Yara, together with Teqplay, has developed advanced planning and performance measurement tools.

Yara’s planning process revolves around accurately forecasting demand and efficiently allocating resources. By integrating demand data into the terminal planner developed with the help of Teqplay, Yara can effectively manage vessel scheduling and optimize key site utilization.

Yara also employs performance measurement systems to track loading efficiency and identify areas for improvement. By monitoring loading rates and downtime, Yara can pinpoint inefficiencies and implement preventive maintenance measures. This proactive approach enhances operational reliability and minimizes disruptions in production.

Simulation tools like Casey are also used to assess the feasibility of new projects and optimize key site configurations. By leveraging the right technology, Yara can make informed decisions to enhance productivity and streamline processes.

Through innovative initiatives and advanced planning tools, Yara continues to navigate the complex maritime landscape while prioritizing environmental concerns. As global food demand rises, Yara’s efforts towards responsible production are essential in ensuring a sustainable future for generations to come.

All blog posts from Navigate 2024