Exposing hidden costs in port calls at Tangier

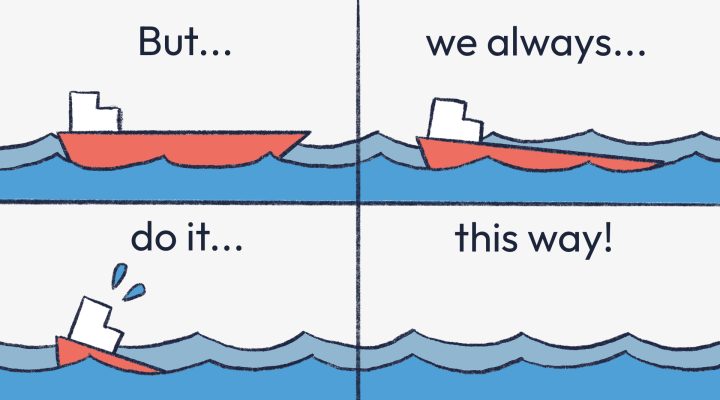

We often talk about inefficiencies in port calls, but what does that really look like? And how can we improve? In Teqplay's latest research, we dived deep into the case of the Port of Tangier, where we uncovered some significant findings on unproductive waiting time in port.